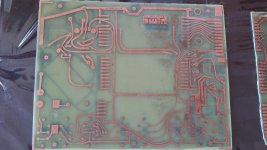

Got all my boards done!

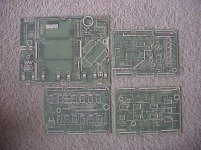

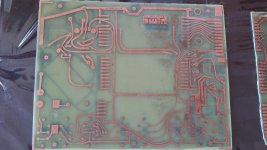

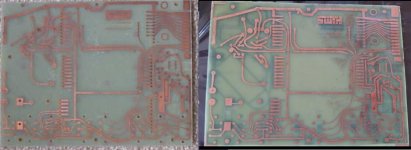

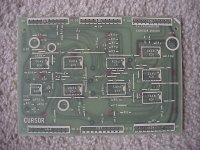

For years this has all been 'theoretical', although I did have the ICs. Having actual boards in hand kind of relights the fire. I've made 5 - the 'mainframe', the timing, cursor and memory board, along with one of Don's earliest ASCII encoders. He designed a few and there is one that came out I think in Nov 1973 -- I'm going to guess he used his original design, although he could have used a prototype of the new one. I like the slow vinegar/peroxide/salt etching process I found.. seems to be fairly gentle (although slow) and I've accidentally splashed some on skin and suffered no adverse effects. Had to remake a couple -- drilling on target is much harder than I thought, and it took me a while to find the best way to cut the boards to their correct side (carbide-tipped laminate scoring tool), so some have some chips from where I was using tin snips. The mainframe is a remake -- and I have to do some cleanup as I failed to put enough vinegar in and the etching process died out before it got all of it.

I have been making many discoveries about parts and so on along the way and slowly unraveling the 'mystery' of how it all went together in the prototype. As mentioned, I believe the case top, from keyboard to backside, is all metal. It became obvious looking at one of the mount points on the board (there are six small L shaped brackets you use to screw the TVT into place, upside down, in whatever case you have) that one of them was a ground, so you'd assume that would require metal. That and my pic of the back kind of put it over the top. I have the correct rocker switches, but I need two more that are momentary DPDT. Found those online pretty easily with correct switch plastic.

I've also found on Michael's site a UART project for the original TVT:

http://www.swtpc.com/mholley/RadioElectronics/Feb1975/RE_Feb_1975_pg52.jpg

I'll probably build that.. would make the TVT a bit more useful. But not sure if I will integrate it into my existing prototype replica or try to use it in the replica of the cover unit I plan to build. I'm concerned that extra board might make the TVT too tall to fit under the prototype case.

I have all the ICs, which is great... I keep hoping to find 2524v shift registers that are 1973 vintage rather than 1976 like I have, but whatever.. I'm just glad I found any at all.

I did make one deviation from the prototype -- 'silkscreening' on the back. Looking at the blank backside I realized having this info for a newbie like me was vital. I have some White Toner Reactive Foil on the way that will transform the black toner transfer I did there to white. Think it'll look pretty good.

The PCBs aren't quite the shade of green I hoped for. That vintage green found on most old PCBs just doesn't seem to exist anywhere. it's either brilliant green or this 'natural' colour I've found. Oh well. Good enough I guess.

Pretty stoked to just get going and building!