Lou - N2MIY

Veteran Member

Folks,

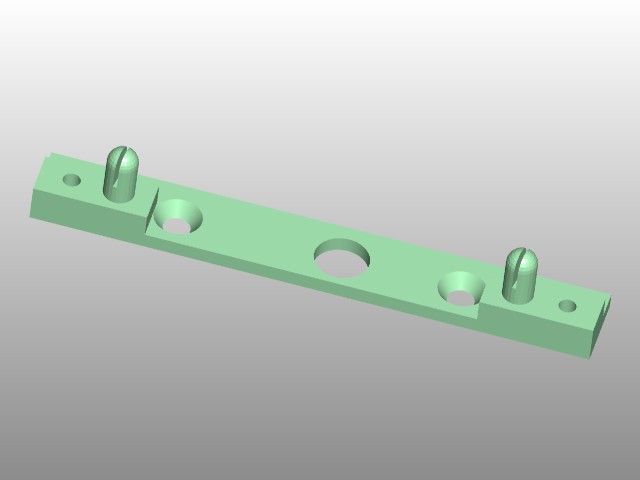

My wife bought my older son a Printrbot Simple 3D printer. It is quite amazing. I thought about the things I wish I could print with it, and one of the first things that came to mind is this bracket : http://www.vcfed.org/forum/album.php?albumid=51&attachmentid=32829

I have only one of these. The wooden thing in the background is my previous sad attempt at making another so that I could at least hold the front of my 8A in place. Has anyone here drawn this part in 3D cad and maybe have a .STL stereolithography file of this?

Thanks,

Lou

My wife bought my older son a Printrbot Simple 3D printer. It is quite amazing. I thought about the things I wish I could print with it, and one of the first things that came to mind is this bracket : http://www.vcfed.org/forum/album.php?albumid=51&attachmentid=32829

I have only one of these. The wooden thing in the background is my previous sad attempt at making another so that I could at least hold the front of my 8A in place. Has anyone here drawn this part in 3D cad and maybe have a .STL stereolithography file of this?

Thanks,

Lou