wolfpup

New Member

- Joined

- Nov 3, 2022

- Messages

- 8

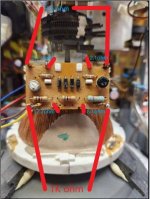

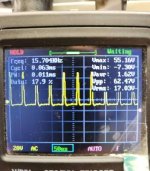

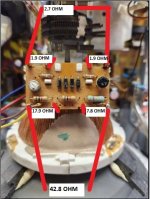

Hi, im new here I want to fix a old apple monitor i have replaced all the electrolytic caps and the IC401 LA7824 this has made no difference the monitor has what kinda looks like vertical collapse

but has wavy lines only in center I have a video of there

anybody have any ideas could this be a bad yoke ? any help on this id be most grateful.

but has wavy lines only in center I have a video of there

anybody have any ideas could this be a bad yoke ? any help on this id be most grateful.