TerryKing

Member

Hello Everyone,

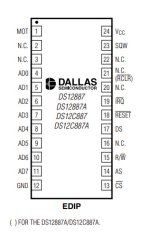

Many have had this dilemma; mine was worse because I have 3 HOT-555 motherboards with the same SOLDERED IN RTC CMOS CHip.

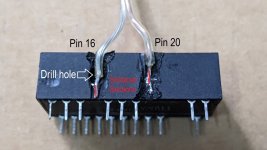

Eventually I got one to work WITHOUT Soldering.. Take a look here:

https://arduinoinfo.mywikis.net/wiki/DS12887A-DALLAS-RTC-DEAD

Let me know if this works for anyone else!

Regards, Terry King

...In The Woods In Vermont

The one who dies with the most Parts LOSES! WHAT DO YOU NEED??

Many have had this dilemma; mine was worse because I have 3 HOT-555 motherboards with the same SOLDERED IN RTC CMOS CHip.

Eventually I got one to work WITHOUT Soldering.. Take a look here:

https://arduinoinfo.mywikis.net/wiki/DS12887A-DALLAS-RTC-DEAD

Let me know if this works for anyone else!

Regards, Terry King

...In The Woods In Vermont

The one who dies with the most Parts LOSES! WHAT DO YOU NEED??