I have a collection of 8 inch and 5¼ inch disks which are difficult to read. I’m looking for advice about ways others have resolved the issues I’m facing.

An important preliminary point is that the disks *look* pristine. There’s little or no evidence of previous damage (e.g. concentric grooves) or contamination with mould. A further point is that the disks were for the ABC-24 and ABC-26 CP/M machines from AI Electronics Corporation of Japan. As far as known, these are the only disks that exist with operating system files and source code for these PCs.

The oxide is extremely fragile. This is probably due to unsatisfactory storage over a period of decades.

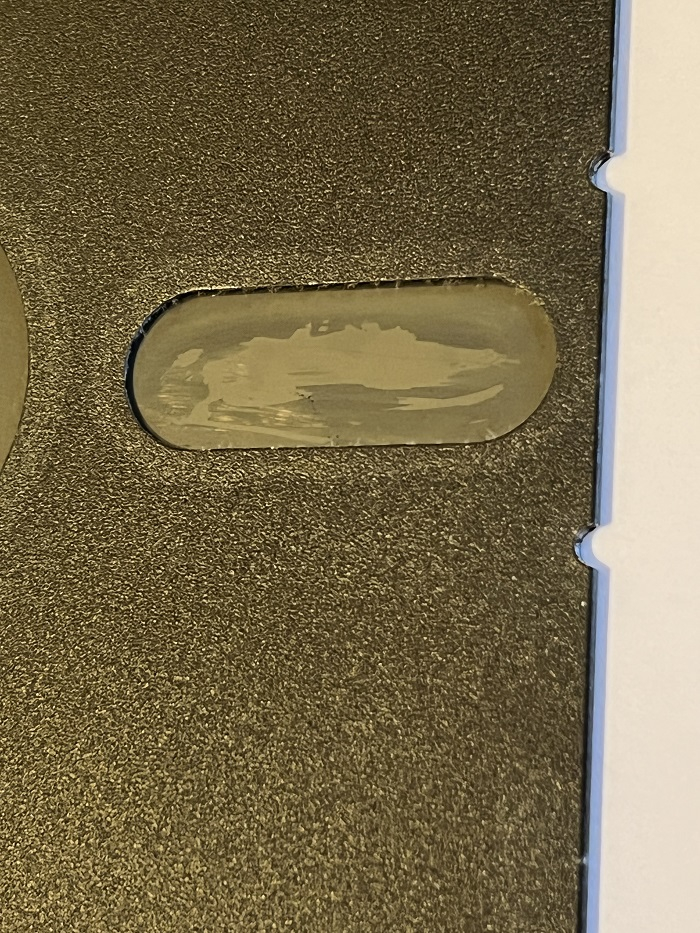

A symptom of the issue is that oxide builds up on the leading edge of the ceramic head – i.e. before the flux transitions can be read. The design of the head was probably intended to stabilise the ‘floppy’ medium as it passed across the head. With this weak oxide, a smaller surface area might be better (e.g. reduced friction).

Digression: ‘Bulldozer’ effect

I have started to think of the drive heads as equivalent to a bulldozer. It the blade starts to collect material, it scrapes deeper in the next tracks to be read. And there’s no bulldozer that doesn’t make a noise. The issue is to find a way to keep the bulldozer floating (silently) rather than digging noisily.

One partial solution may be to remove the ‘doughnut’ from the original sleeve and insert it in a sleeve from a disk that has never been used – on the basis that the latter may have less dirt adhering to the fabric that originally provided lubrication. That doesn’t seem to address the problem, but it’s easy to do.

One solution may be to reduce friction between the head and the surface of the disk. It could be helpful to adjust the head load of the drive (but that isn’t an obvious way to read the data first time). Perhaps some surface treatment exists that could make the disk less affected by friction or more resilient to contact with the head.

What works?

It doesn’t seem practical to alter the profile of read/write heads of any drive. So, the question is: “what works to stabilise the oxide of the floppy disks?”.

Heat?

I’m aware that in the audio tape recovery environment, gentle heat for a period of time is the approach to tackle ‘sticky shed’. I think this approach has been used with QIC catridges and 9 track tape. Has anyone successfully used this approach for floppies?

Chemicals?

I have seen references to chemicals that may help to deal with mould or other surface contaminants. I’ve seen some advocates of IPA and others who warn against it. Are there recommended discussions to find?

What is best for cleaning the heads?

Far more time is devoted to cleaning the read heads of the drive than reading the disks. What has been found most effective (excluding ultrasound, which would mean removal of the heads from the drives)?

Usual approach

Some background information. I have several Shugart 8 inch and Teac 5¼ inch drives used regularly and known to be well-calibrated. And other drives to use if these fail.

My usual approach with late 1970s and early 1980s disks is to read tracks 0-4 and then examine the read-write heads. The drive is on the workbench (not in a case) with a bright light to inspect the heads. I use a Q-tip taped to the end of a thin stick of wood (‘coffee stirrer’) to access the head from the side after soaking the tip in 95-99% Isopropyl Alcohol. Sideways scrubbing eventually gets rid of the visible oxide residue. Light pressure on the upper head is required when double-sided disks are involved.

In a few cases, when there is no evidence of oxide left on the head from tracks 0-4, I may increase the number of tracks read next time, say tracks 5-14. If there’s still no oxide when I get to around track 35, I may read tracks 36-76 in a single operation.

With a collection of disks, I check the data recovered in a hex viewer from the first few disks. If that suggests poor capture, I’ll try a different drive.

What other information would be useful?

Thanks in advance.

An important preliminary point is that the disks *look* pristine. There’s little or no evidence of previous damage (e.g. concentric grooves) or contamination with mould. A further point is that the disks were for the ABC-24 and ABC-26 CP/M machines from AI Electronics Corporation of Japan. As far as known, these are the only disks that exist with operating system files and source code for these PCs.

The oxide is extremely fragile. This is probably due to unsatisfactory storage over a period of decades.

A symptom of the issue is that oxide builds up on the leading edge of the ceramic head – i.e. before the flux transitions can be read. The design of the head was probably intended to stabilise the ‘floppy’ medium as it passed across the head. With this weak oxide, a smaller surface area might be better (e.g. reduced friction).

Digression: ‘Bulldozer’ effect

I have started to think of the drive heads as equivalent to a bulldozer. It the blade starts to collect material, it scrapes deeper in the next tracks to be read. And there’s no bulldozer that doesn’t make a noise. The issue is to find a way to keep the bulldozer floating (silently) rather than digging noisily.

One partial solution may be to remove the ‘doughnut’ from the original sleeve and insert it in a sleeve from a disk that has never been used – on the basis that the latter may have less dirt adhering to the fabric that originally provided lubrication. That doesn’t seem to address the problem, but it’s easy to do.

One solution may be to reduce friction between the head and the surface of the disk. It could be helpful to adjust the head load of the drive (but that isn’t an obvious way to read the data first time). Perhaps some surface treatment exists that could make the disk less affected by friction or more resilient to contact with the head.

What works?

It doesn’t seem practical to alter the profile of read/write heads of any drive. So, the question is: “what works to stabilise the oxide of the floppy disks?”.

Heat?

I’m aware that in the audio tape recovery environment, gentle heat for a period of time is the approach to tackle ‘sticky shed’. I think this approach has been used with QIC catridges and 9 track tape. Has anyone successfully used this approach for floppies?

Chemicals?

I have seen references to chemicals that may help to deal with mould or other surface contaminants. I’ve seen some advocates of IPA and others who warn against it. Are there recommended discussions to find?

What is best for cleaning the heads?

Far more time is devoted to cleaning the read heads of the drive than reading the disks. What has been found most effective (excluding ultrasound, which would mean removal of the heads from the drives)?

Usual approach

Some background information. I have several Shugart 8 inch and Teac 5¼ inch drives used regularly and known to be well-calibrated. And other drives to use if these fail.

My usual approach with late 1970s and early 1980s disks is to read tracks 0-4 and then examine the read-write heads. The drive is on the workbench (not in a case) with a bright light to inspect the heads. I use a Q-tip taped to the end of a thin stick of wood (‘coffee stirrer’) to access the head from the side after soaking the tip in 95-99% Isopropyl Alcohol. Sideways scrubbing eventually gets rid of the visible oxide residue. Light pressure on the upper head is required when double-sided disks are involved.

In a few cases, when there is no evidence of oxide left on the head from tracks 0-4, I may increase the number of tracks read next time, say tracks 5-14. If there’s still no oxide when I get to around track 35, I may read tracks 36-76 in a single operation.

With a collection of disks, I check the data recovered in a hex viewer from the first few disks. If that suggests poor capture, I’ll try a different drive.

What other information would be useful?

Thanks in advance.