I've recently got a buckling spring keyboard for the price of postage. Unfortunately the case is cracked in few places (all pieces are present so I can glue it back) and it has few issues.

First was that 0 woukd press itself all the time. It turned out the spring under that key was slightly longer. Swapping it with another appeared to fix it.

Then a number of keys on the num pad didn't work at all.

I've disassembled it and I cleaned the membrane with contacts cleaner (including board connections), but still I have keys that don't work. It appears two traces are not making proper contact from the membrane to the pcb.

I tried contact cleaner on qtips plus alcohol with no results. Is it worth using very fine sandpaper? (2000 grit automotive bodywork kind)?

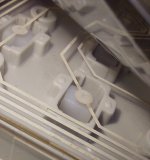

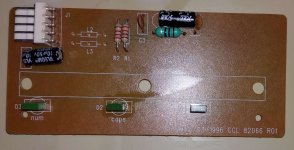

This is how the membrane is connected to the pcb

Here is a closeup (both parts can be disassembled and I cleaned it inside, but I didn't take any pictures.

And here is the front (I've removed one keycap and spring)

Does anyone have any advice? (other than buying a working one...)

First was that 0 woukd press itself all the time. It turned out the spring under that key was slightly longer. Swapping it with another appeared to fix it.

Then a number of keys on the num pad didn't work at all.

I've disassembled it and I cleaned the membrane with contacts cleaner (including board connections), but still I have keys that don't work. It appears two traces are not making proper contact from the membrane to the pcb.

I tried contact cleaner on qtips plus alcohol with no results. Is it worth using very fine sandpaper? (2000 grit automotive bodywork kind)?

This is how the membrane is connected to the pcb

Here is a closeup (both parts can be disassembled and I cleaned it inside, but I didn't take any pictures.

And here is the front (I've removed one keycap and spring)

Does anyone have any advice? (other than buying a working one...)