Well diagnosing WHY the transistor exploded was fun.

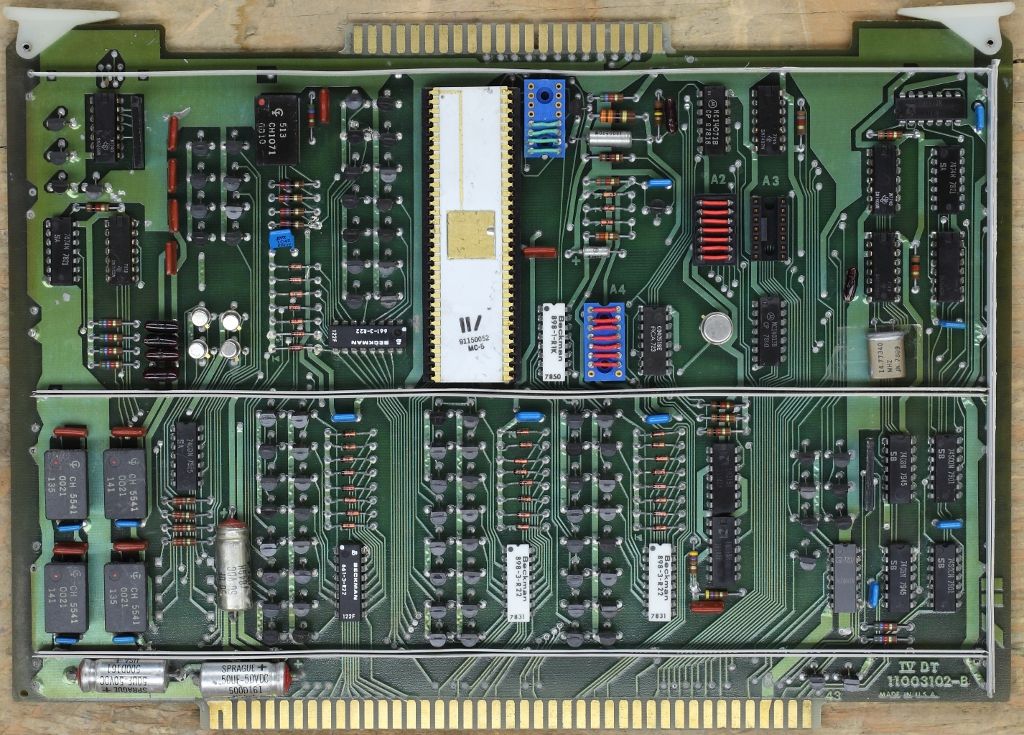

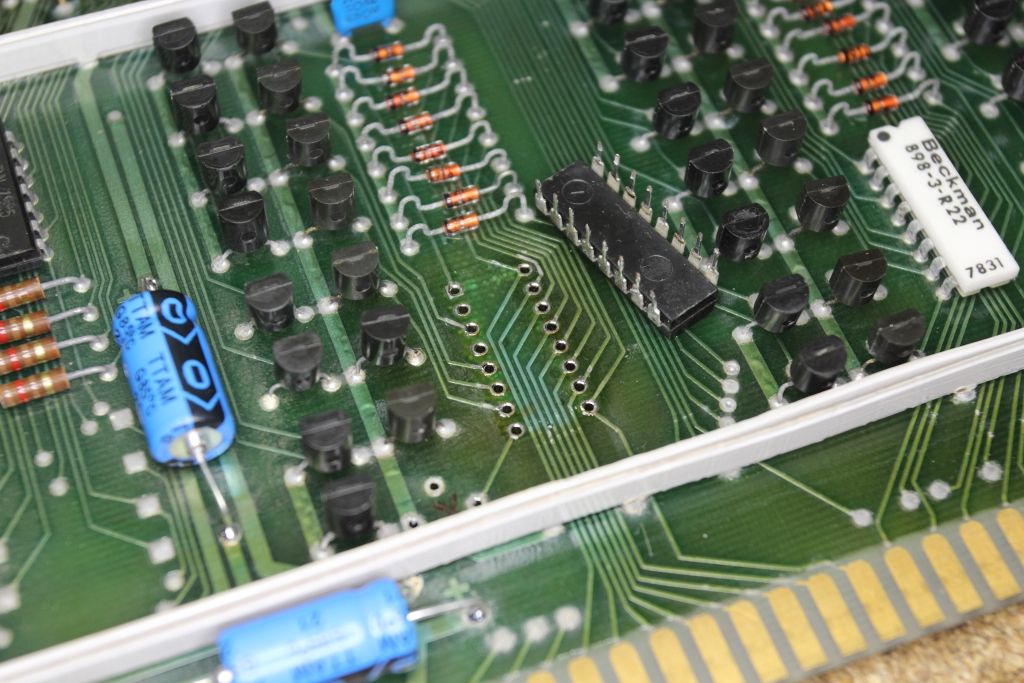

So I started by removing the resistor network, then I was able to check the group of diodes. They tested fine. I ahve not tested the network but I'm guessing that's fine too.

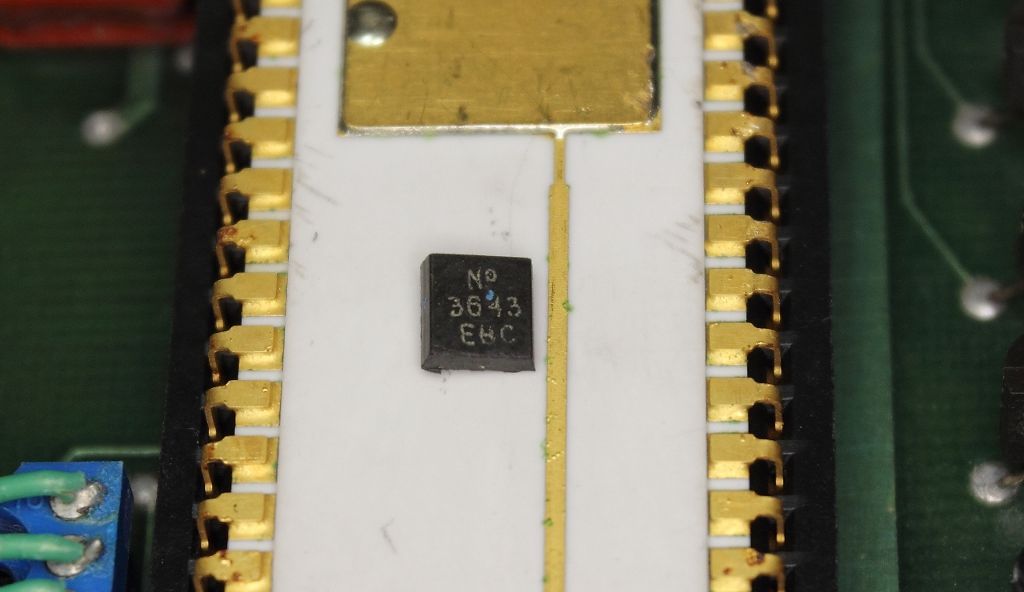

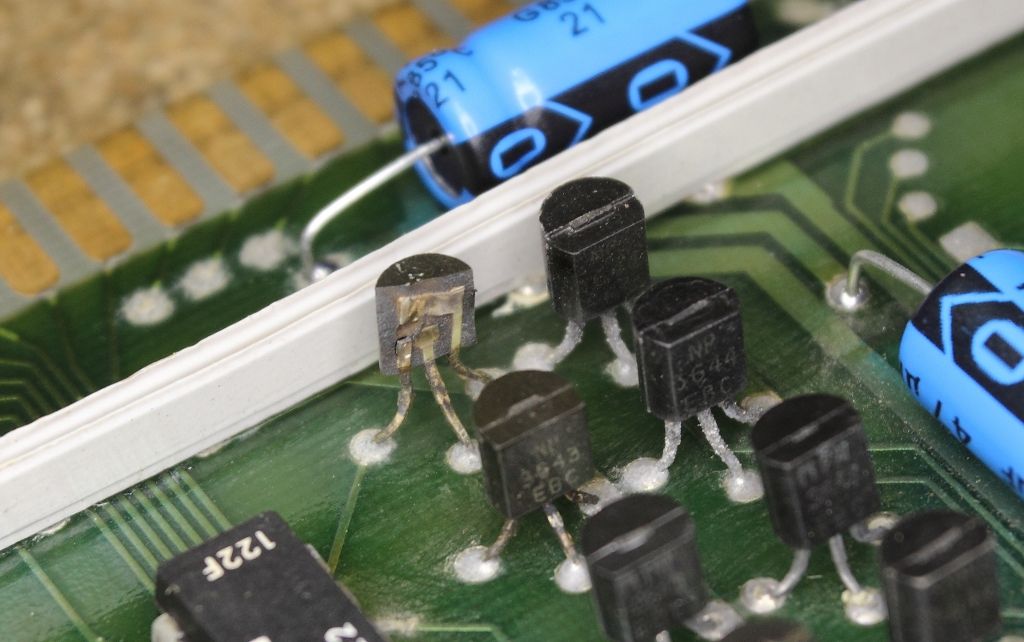

With that removed I plugged it back in and let it cook for 20 seconds with the power on. The thermal camera now saw a single 2N3643 transistor in the lineup that was abnormally warm. Pulled it out and it tested fine. Huh...

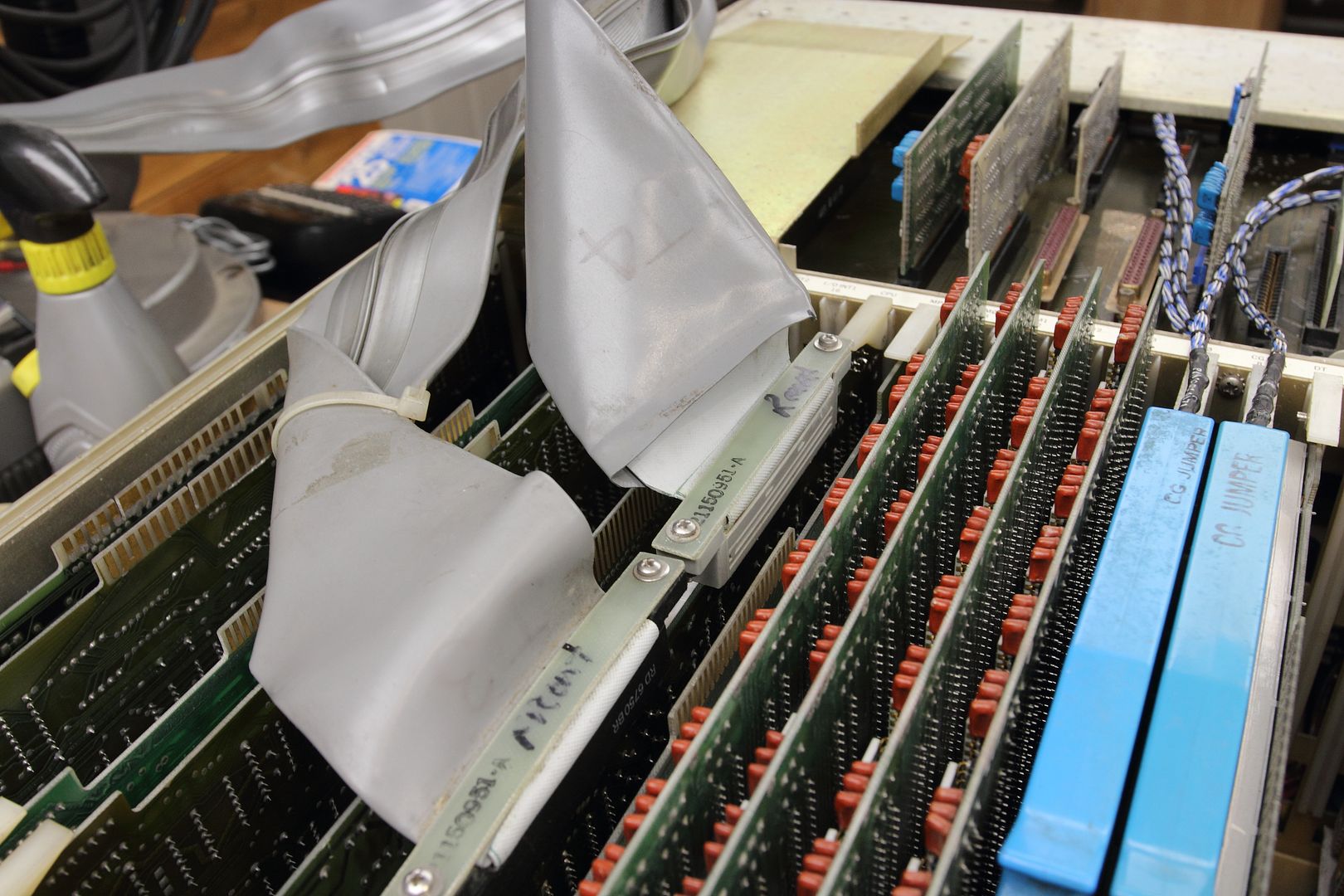

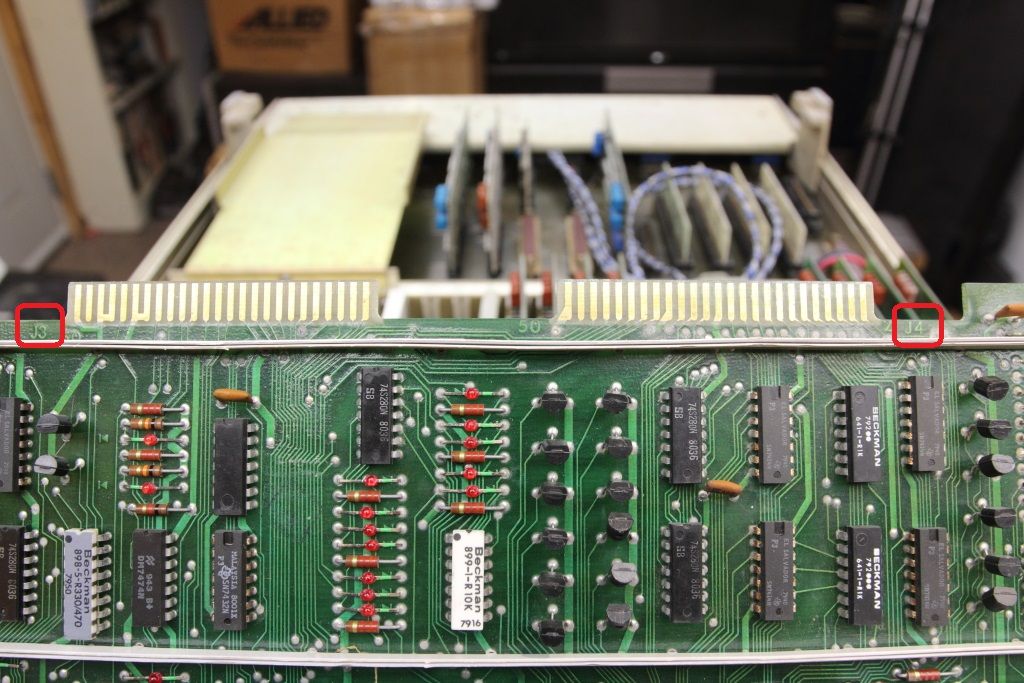

So each 2N3643 in the lineup is complimented by a 2N3644 next to it. I'm not entirely sure why but there's two other similar banks of transistors like this with a row of diodes and a resistor network so I can only guess my fault might be in these transistors, should any be leaking and driving the other transistor next to it to the point of blowing up.

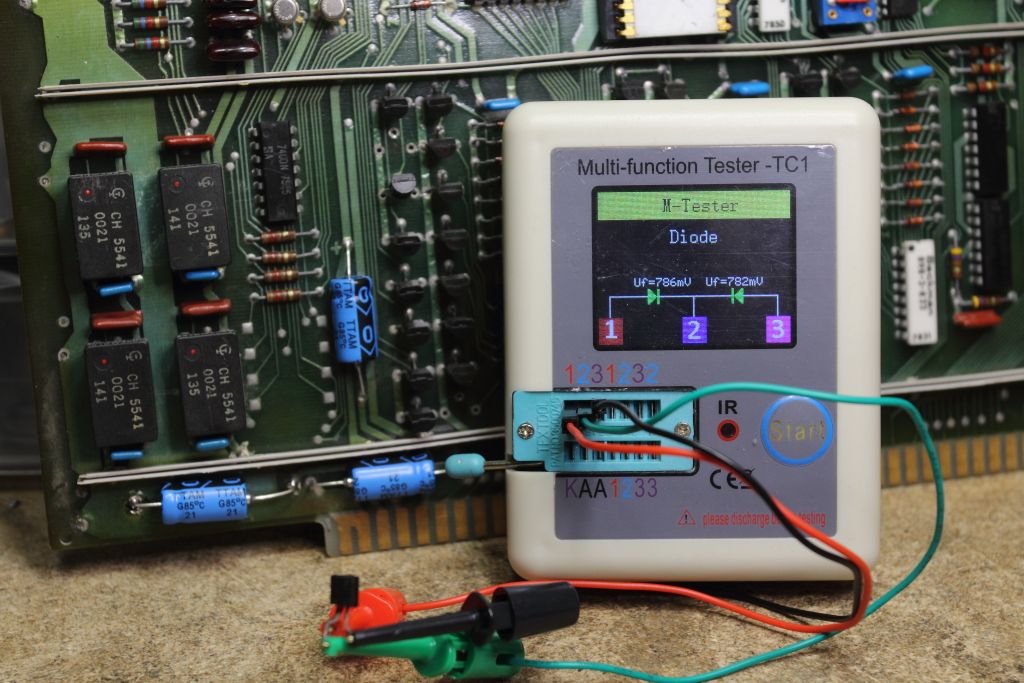

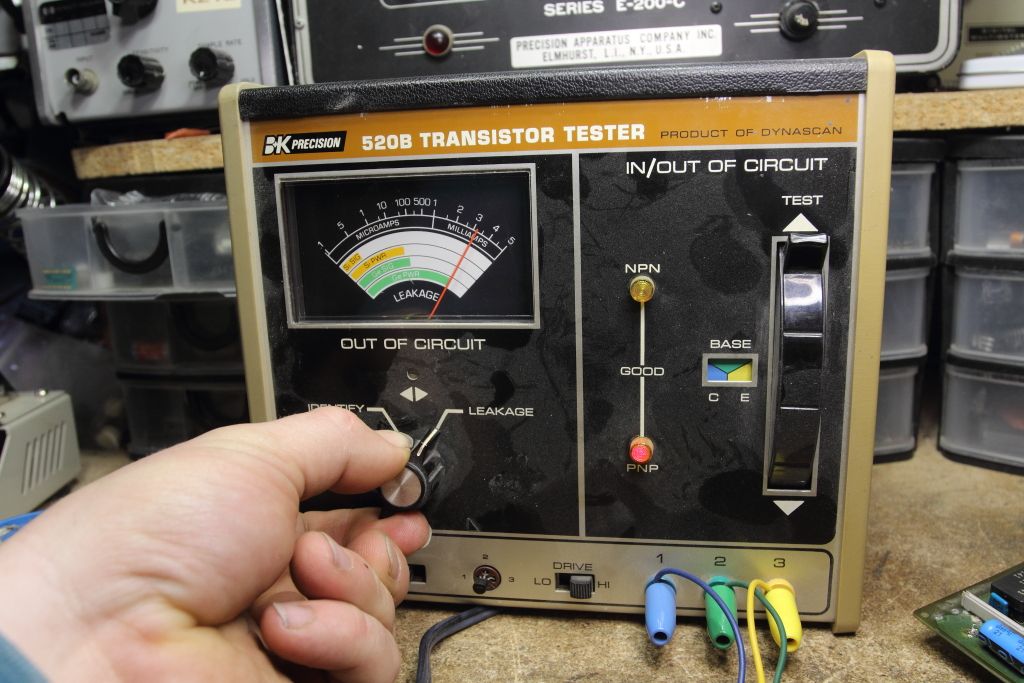

Found two that were bad. One read as two diodes, the other (that was paired with the first transistor that blew up) was so thwacked it was putting the tester into self-test mode, so I put it into the BK Precision tester and it saw it as VERY leaky.

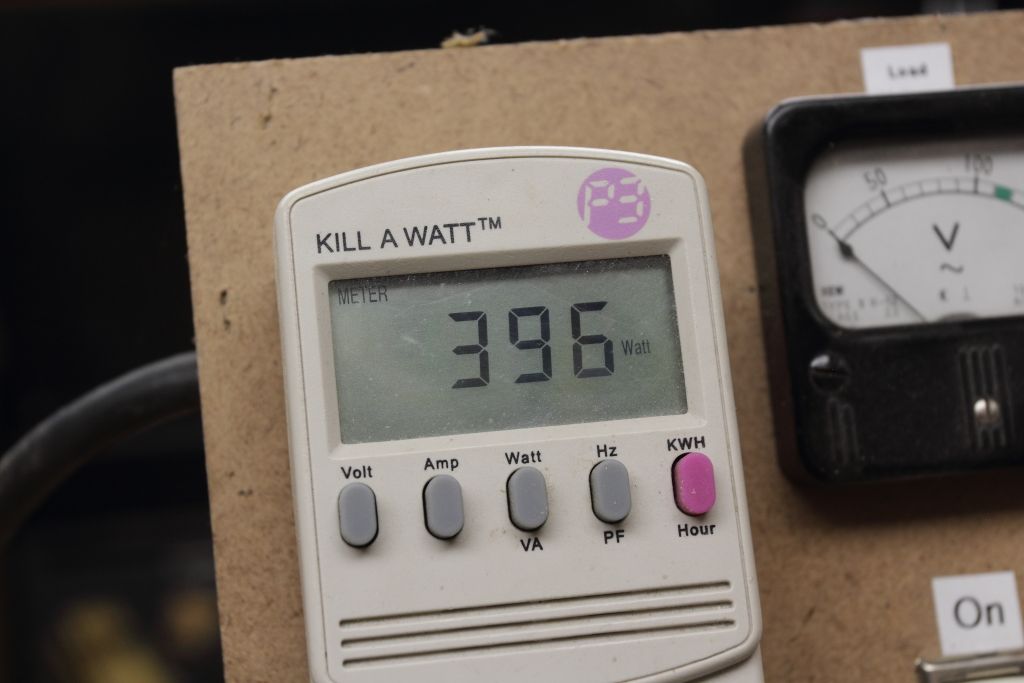

Alright well that would explain why the transistors were unhappy. So I pulled out three bad transistors in all, put the resistor network back in and put that back in the machine and let it soak for another 30 seconds. Pulled it out and found two more transistors that were getting hot along with the network. Neither had tested bad previous but one I had already marked as our original transistor that I saw getting hot and I had since moved it to a different location and the fault moved with it, so it these must be damaged in some way the tester can't catch. After pulling those I ran it for another minute and the thermal camera no longer found any more hotspots or an overheating resistor network.

So in all, six bad transistors to be replaced. Three 1N3643's and three 2N3644's.

Edited: well even though we got a bunch of transistors now missing the machine has now passed a five minute run test without burning up again so I'll oil the main fans, fabricate a cover for the machine and put it in for an extended burn-in.