true. I did some adjusting today and was able to pull the image to the right by maxing out the h.hold. Then tested the monitor on two other sources: an apple //c and one of those battery powered plug & play tv games (I keep that around as a quick and dirty composite video source for testing)

Between using the PET and the other two I had to adjust the v.hold and v.size (both of which are accessible from the external pots) but after doing that the apple looked great and the tv game wasn't bad, it was off the screen a bit on both sides but it was like that before doing all of this.

Yes, if the H hold pot is adjusted the picture (data inside the raster scan timing) will shift left & right. But if that is used as a tool to do it, and it is displaced too far one way, sometimes when the set is switched on and off, the H osc won't re-capture.

In the TV industry the horizontal oscillator's control is called an AFC (automatic frequency control), but actually it is a typical PLL circuit. The H osc itself is set up to be a VCO and is controlled by a filtered error voltage that represents the difference in frequency of the H osc and the incoming H sync. The signal that represents the H osc, is often taken from a high voltage point in the Flyback area, fed back and filtered with an RC network and compared with the incoming H sync in a circuit with a pair of diodes. The diode output generates the error voltage stored on a capacitor, reminiscent of a sample hold circuit. In parallel with that capacitor is a series RC combination which is the "anti-hunt" network seen in most PLL circuits. It is the feedback pathway that can be altered to adjust the H position of the image, when the H osc is locked:

By altering a capacitor and or resistor in the PLL feedback loop leading to the diodes, which is difficult without the schematic (which is why I did not suggest it).

In some VDU's they added an independent control for this called the H. Phase control, I would doubt your Apple VDU has such a control, it was more common in color VDU's, but it might.

When it comes to finding the correct setting for the H hold control, it often baffles people because once in lock appears to remain in lock , once captured, over a large range of positions of the control. The way to adjust it and know 100% it is correct , is to disconnect the H sync feed or remove that from the composite signal, which is easily done if the composite signal is generated by the adapter, then set the H hold control so that the picture/ image is just barely floating by horizontally, then you have set the H osc's free run frequency to match the sync frequency.Then reconnect the H sync.

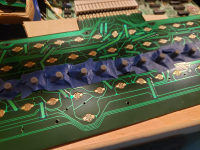

Probably on your VDU, by the look of it, you could reduce the scan width if you wanted to, it is an inductor in series with the yoke's H coil that has (normally) a ferrite slug. If you do it, only use a plastic tool, never metal or it can crack the slug.

Most TV's were set up by the manufacturer with moderate over-scan of the CRT face and therefore some of the raster edges not visible. Some computer VDU's though were set up with just a tad of overscan where the raster edges just overlapped the screen perimeter and others slightly under-scanned an not even reaching the CRT perimeter.