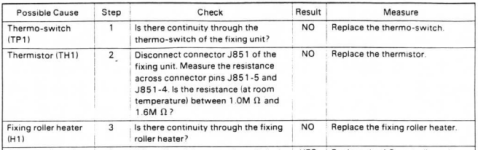

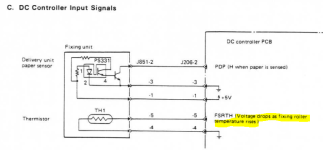

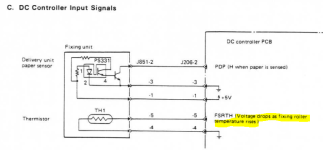

Yup, definitely a problem with the fuser circuit. Doesn't get hot and this stays around 4.5-5 Volts:

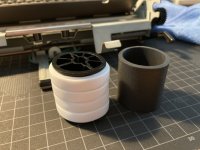

@Paolo B, do you mind measuring the heater lamp resistance if it's not too much of a hassle? I'm going to get it out after replacing the cap if there's still no heat from the lamp

I'll try procuring the correct capacitor, as it plays a role in the protection circuit:Going too high of a voltage can be a problem, because high voltage capacitors have a different internal plate layout that changes their characteristics.

From 35 to 50v generally isn't an issue, but to 63v is when the internal plate layout starts to change. This usually results in substantially different ESR.

If the circuit works, I'd monitor it for awhile to see if anything is getting excessively hot. If you start having weird phantom problems, remember that capacitor, as it may be the culprit.

@Paolo B, do you mind measuring the heater lamp resistance if it's not too much of a hassle? I'm going to get it out after replacing the cap if there's still no heat from the lamp