BrainStruck

Member

Hi,

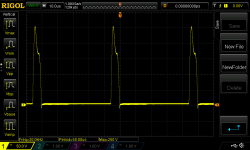

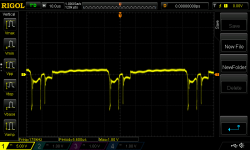

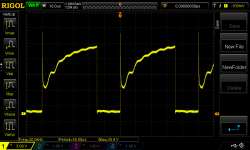

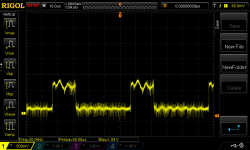

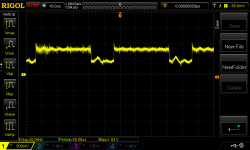

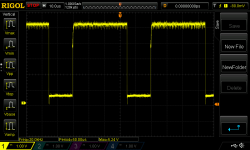

I'm in the process of restoring a PET 4032 and I cannot seem to get any video out of it. I'm using the pettest ROM right now to try to test the screen. I have horizontal and vertical sync signals. I have a video signal. I went through the Commodore 4000 Series Technical Manual and checked all 18 of the test points on the monitor and I'm getting the appropriate signals on an oscilloscope. The CRT filament is lit up but no matter how I adjust the brightness, sub brightness, and focus, I cannot seem to get any video.

What I have done:

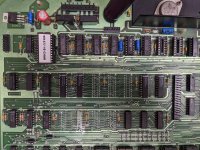

Replaced all diodes including the zener diode on the high voltage hold down circuit

Replaced the polypropylene caps

Replaced the safety cap (0.015uf / 630v) next to the LOPT (this one smoked when I turned it on - typical for a RIFA)

Replaced 3 electrolytic caps that looked like they leaked

What I have NOT done:

Replaced the rest of the electrolytic caps that looked fine

Does anyone have any ideas?

Thanks,

Brian

I'm in the process of restoring a PET 4032 and I cannot seem to get any video out of it. I'm using the pettest ROM right now to try to test the screen. I have horizontal and vertical sync signals. I have a video signal. I went through the Commodore 4000 Series Technical Manual and checked all 18 of the test points on the monitor and I'm getting the appropriate signals on an oscilloscope. The CRT filament is lit up but no matter how I adjust the brightness, sub brightness, and focus, I cannot seem to get any video.

What I have done:

Replaced all diodes including the zener diode on the high voltage hold down circuit

Replaced the polypropylene caps

Replaced the safety cap (0.015uf / 630v) next to the LOPT (this one smoked when I turned it on - typical for a RIFA)

Replaced 3 electrolytic caps that looked like they leaked

What I have NOT done:

Replaced the rest of the electrolytic caps that looked fine

Does anyone have any ideas?

Thanks,

Brian