Ok, the boost buck came early, so the past few evenings I've assembled the 2nd PSU replacement for an IBM 5110 based on the MeansWell PSU.

I believe this would also work for an IBM 5100 (same dimensions and the Y1 connector pinouts on the A1 board is the same).

BOARD

I ordered a thicker acrylic boards from Professional Plastics. They weren't very expensive, except they had a minimum order of $25, so I've ended up with 4 boards.

The dimensions I use were:

0.187 THICK CLEAR EXTRUDED ACRYLIC FILM-MASKED SHEET [Per Piece]

Size: 10.62" X 6.10" @ +/- 0.031

[ approximately 4.7mm thick -- I think the next step up was 5.5mm thick and that would have worked fine, but I went conservative and selected the 4.7mm one ]

The size of the cut was spot on to the original PSU PCB, so very happy with that. Mounting holes were easy, just drilled at a medium speed (at least to start) - no cracks, light sanding to clean up the bores a bit.

ACTUAL PSU

The actual AC/DC conversion it from a pre-built MeanWell PSU. A little bit long (thus more weight), but passive (no fans).

MeanWell RQ-128B, which provides +5V +12V -5V -12V (from DigitKey).

To "boost" the 5V line to 8.5V, I used the following generic device:

HiLetgo LTC1871 DC-DC Step Up Booster Converter 3-35VDC to 3.5-35VDC With LED Voltmeter DC-DC Step Up Module Power Supply Voltage Regulator

The LED just shows the input or output voltage (no temperature), and the LED can be turned off (once have the desired conversion, can turn off the LED to eliminate any red light and slightly reduce some draw).

WORK

From there, it is making a bunch of spade connectors to be compatible with the original Y1 wiring harness (two different sizes). It was a compromise between making these longer-than-needed for convenience (when it comes to actually installing inside the IBM 5110 PSU bay area), but not too long that it overly clutters up that PSU bay. Then used a clear rubber "boot" between each connection, so the metal of certain wires never inadvertently touches another. So stripping, crimping, testing.

Previously I used a set of buck-boost DC adapters, and that still works in another 5110. But for being about the same cost (still under 100 bucks in parts), I do like this updated version better (a slightly smaller version of the RQ-128B would be nice -- but the one here is still plenty compact enough).

Here's how it turned out. I am trusting it enough to close things up and make it the permanent PSU I used for this particular 5110. Next, I'm waiting for an o-scope to arrive to start looking into building a keyboard replacement (or at least some way to drive inputs).

1) Size comparison with stock IBM 5110 PSU

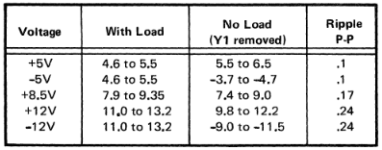

2) Fitment complete. Testing all the Y1 pins before actually connecting to the A1 board (also tested before actually fitting the board into the bay). The top screws are all fine, but behind the external ports, I actually missed on the lower holes (drilled them slightly too high, but not a huge deal since the external ports are securely screwed down and hold the bottom half of the PSU anyway).

3) Still a prototype, to verify fit and drilled placements, etc. I left the blue sticker on one side of the acrylic, giving this effect from the backside of the unit (a nice "Big Blue" effect, although I think that IBM slogan didn't really start until the 1980s)

4) The system boots with this PSU, that has been secured into the same spot as the stock PSU! Here it is at the BASIC prompt. Now to start work on a keyboard alternative. (some might recognize this one, I used it in the PALM assembler/machine code demo).

I do have another 5110 that is 100% all original parts, down to every screw (and original price receipt and metal serial plaque). So it's fun having a 2nd to be more experimental with.

Well, waiting for some thicker acrylic boards anyway.

Well, waiting for some thicker acrylic boards anyway.