voidstar78

Veteran Member

I was thinking about the note of the head possibly being tilted.

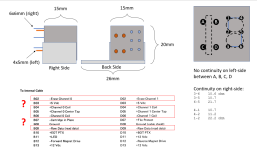

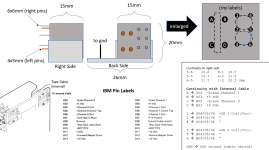

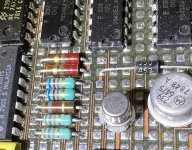

The bracket that the black grounding wire attaches to is "sunk" into the plastic, giving a fairly sturdy base (and a level surface). It may be hard to visualize the image below without being familiar with the tape deck arrangement - but the image is with the tape-drive PCB logic board removed.

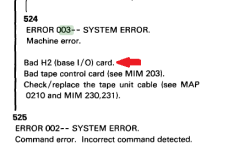

It occurred to me that if that black ground wire was loose, perhaps the other wires behind the head might also be loose? (especially since I think they are supposed to be tucked in behind that enclosure, not to the side). So I took the metal shroud off (since I think in reviewing the 5100 MIM, it didn't show having that shroud enclosure around the head - the Edwin Starr song "what is it good for, absolutely nothin'" came to mind). I buttoned everything back together (sans shroud), but still same 003 E80 error result during MARK. (and the cables behind this electro-mag all seemed secured).

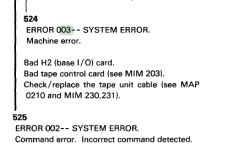

I also took the Common/Language ROS from the 5110 Type2 (type2's don't have internal tape drive) and placed it in the Type1, to see if it would respond to tape commands - and it does! Same results (REWIND works, MARK rewinds to the single dot mark then gives an 003 error), but the fact that tape commands are responding at all gives me hope that a tape unit could be retrofitted into a 5110 Type2.

The bracket that the black grounding wire attaches to is "sunk" into the plastic, giving a fairly sturdy base (and a level surface). It may be hard to visualize the image below without being familiar with the tape deck arrangement - but the image is with the tape-drive PCB logic board removed.

It occurred to me that if that black ground wire was loose, perhaps the other wires behind the head might also be loose? (especially since I think they are supposed to be tucked in behind that enclosure, not to the side). So I took the metal shroud off (since I think in reviewing the 5100 MIM, it didn't show having that shroud enclosure around the head - the Edwin Starr song "what is it good for, absolutely nothin'" came to mind). I buttoned everything back together (sans shroud), but still same 003 E80 error result during MARK. (and the cables behind this electro-mag all seemed secured).

I also took the Common/Language ROS from the 5110 Type2 (type2's don't have internal tape drive) and placed it in the Type1, to see if it would respond to tape commands - and it does! Same results (REWIND works, MARK rewinds to the single dot mark then gives an 003 error), but the fact that tape commands are responding at all gives me hope that a tape unit could be retrofitted into a 5110 Type2.