NeXT

Veteran Member

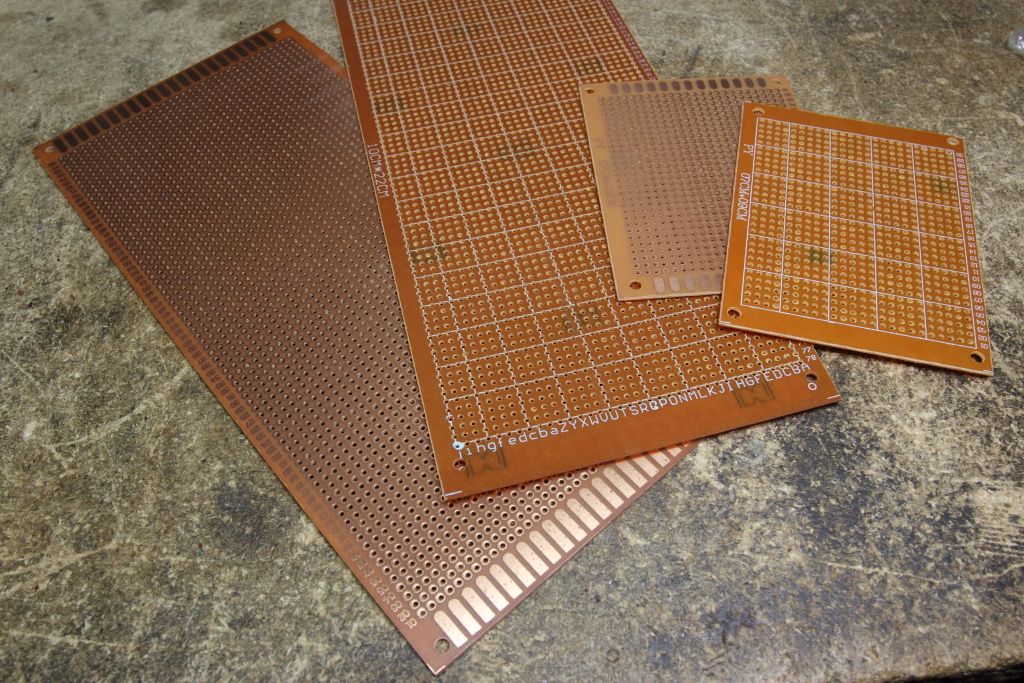

I was trying to finish a project this weekend and realized I had run out of 4" x 8" sheets of Veroboard. I've spent the last two days now trying to find more but it seems the official Veroboard source I last bought from a decade ago has since closed and their website is now dedicated to lighting and all the stuff I'm getting out of china is inferior. I'm a huge fan of the single-side dotted board because I can score and snap it to whatever size I needed but I can only find it cheap in small 50mm x 70mm pieces which after ordering from two lots have absolutely trash hole alignment.

That isn't your eyes acting up. It's just that garbage.

Larger sheets have massive edge margins and additional solder pads/edge connectors and I'm not paying $15 a sheet for this garbage. The other option it keeps giving me is stripboard. I hate that stuff. What on earth happened to dotted prototyping board?

That isn't your eyes acting up. It's just that garbage.

Larger sheets have massive edge margins and additional solder pads/edge connectors and I'm not paying $15 a sheet for this garbage. The other option it keeps giving me is stripboard. I hate that stuff. What on earth happened to dotted prototyping board?

Last edited: