Upcoming Events:

- VCF South West - June 14 - 16, Davidson-Gundy Alumni Center at University of Texas at Dallas

- VCF West - Aug 2 - 3, Computer History Museum, Mountain View, CA

- VCF Midwest - Sept 7 - 8 2024, Schaumburg, IL

- VCF SoCal - Mid February 2025, Location TBD, Southern CA

- VCF East - April 2025, Infoage Museum, Wall NJ

-

Please review our updated Terms and Rules here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Virtual DEC KEY REPOSITORY

- Thread starter RSX11M+

- Start date

RSX11M+

Veteran Member

- Joined

- Feb 14, 2011

- Messages

- 1,075

Very cool. I'd volunteer but don't have a machine to check out that one. I do want one though, maybe I could get the first one to result from our efforts?

Which code did you use? 7654321:5173757 hopefully.

Lou was first to put his hat in the ring for testing.

Which code did you use? 7654321:5173757 hopefully.

Lou was first to put his hat in the ring for testing.

Last edited:

Lou - N2MIY

Veteran Member

I'll certainly volunteer to test this key, but someone who is in need of this key should speak up, since I am fortunate enough to already have one.

Lou

Lou

NF6X

Veteran Member

Yes, I used 7654321:5173757. I got a request by PM from somebody who has one key and two machines. Here's what I'm doing: I'm making two copies of the key that I cut yesterday, then sending one each to Lou and the guy who's short one key. If they both work well, then I'll know that I have a good master to make copies. Lou offered to send back the key if it works, but I've instead asked him to pass it along to the next person who needs one. How's that for a plan?

I didn't stamp anything on the bow of the key, so it won't be mistaken for an original.

I didn't stamp anything on the bow of the key, so it won't be mistaken for an original.

RSX11M+

Veteran Member

- Joined

- Feb 14, 2011

- Messages

- 1,075

An appeal for more DEC key holders

An appeal for more DEC key holders

We've made a good start here, with many PDP-11 owners reporting their key's numbers and by now most of the PDP-8 types. While we have yet to hear from owners of all PDP-11 variations, we have only heard from one VAX owner (myself) and none of the PDP-10 family.

KL10 CPU consoles had an ACE key, as did the KS10 (DEC20 line). The KA10s I know of did not, but I'm unsure what other family members had them or when they were imbued with Keys, or which. So a call out to previous PDP-10 admins out there... (e.g. - Clive Dawson - You still out there?) - please stop by and tell us of any keys or recollections you have about these types.

You will see our posts, and know our purpose in asking. Thank you.

An appeal for more DEC key holders

We've made a good start here, with many PDP-11 owners reporting their key's numbers and by now most of the PDP-8 types. While we have yet to hear from owners of all PDP-11 variations, we have only heard from one VAX owner (myself) and none of the PDP-10 family.

KL10 CPU consoles had an ACE key, as did the KS10 (DEC20 line). The KA10s I know of did not, but I'm unsure what other family members had them or when they were imbued with Keys, or which. So a call out to previous PDP-10 admins out there... (e.g. - Clive Dawson - You still out there?) - please stop by and tell us of any keys or recollections you have about these types.

You will see our posts, and know our purpose in asking. Thank you.

pbirkel@gmail.com

Veteran Member

Received a key today. Tried it out on both an 8/L and an 11/20. No luck with either. I'm no locksmith but I have three observations:

1. Compared to my existing key, there's a lot of pin-clicking on insertion, particularly as the key reaches full depth. The existing key is practically silent going either in or out. With the old key both directions are almost frictionless (as if nothing is happening at all!), whereas the new key clearly is engaging/disengaging mechanism(s)/pin(s) as it moves in and out.

2. Visibly (to my naked eye) all of the notches in the new/old key follow the same pattern but the new key appears to have consistently longer notches than the old one -- enough so that the shortest old-notch is at least twice as long in the new key (actually, a bit more because in the old key the shortest notch is a bare smidgen in length). BTW, the smidgen-notch is located at 3 o'clock when sighting into the barrel with the alignment-tab ("gun sight") aligned at 11 o'clock.

3. Examining the notch-alignment around the circumference based on their positioning relative to the alignment-tab ("gun sight") it's clear that the new-key is notch-misaligned. I estimate that the notch-pattern is rotated roughly 20 degrees clockwise compared to the old-key. The old-key is pretty symmetrical; the new-key is rather asymmetrical as regards notch-position :-<.

Observation #1 might be related to wear (lack of). Observation #2 suggests to me to try filing the new key shorter until the notch-length appears to either visibly correspond to that of the old key or it begins to work. Don't know if that's a good idea, or not, to try. Comments? Observation #3 suggests to me that length-reduction is probably not going to improve matters as the notches are incorrectly positioned WRT the alignment-tab ("gun sight").

Interested in hearing from others whether their experience is consistent with mine ... or not.

paul

1. Compared to my existing key, there's a lot of pin-clicking on insertion, particularly as the key reaches full depth. The existing key is practically silent going either in or out. With the old key both directions are almost frictionless (as if nothing is happening at all!), whereas the new key clearly is engaging/disengaging mechanism(s)/pin(s) as it moves in and out.

2. Visibly (to my naked eye) all of the notches in the new/old key follow the same pattern but the new key appears to have consistently longer notches than the old one -- enough so that the shortest old-notch is at least twice as long in the new key (actually, a bit more because in the old key the shortest notch is a bare smidgen in length). BTW, the smidgen-notch is located at 3 o'clock when sighting into the barrel with the alignment-tab ("gun sight") aligned at 11 o'clock.

3. Examining the notch-alignment around the circumference based on their positioning relative to the alignment-tab ("gun sight") it's clear that the new-key is notch-misaligned. I estimate that the notch-pattern is rotated roughly 20 degrees clockwise compared to the old-key. The old-key is pretty symmetrical; the new-key is rather asymmetrical as regards notch-position :-<.

Observation #1 might be related to wear (lack of). Observation #2 suggests to me to try filing the new key shorter until the notch-length appears to either visibly correspond to that of the old key or it begins to work. Don't know if that's a good idea, or not, to try. Comments? Observation #3 suggests to me that length-reduction is probably not going to improve matters as the notches are incorrectly positioned WRT the alignment-tab ("gun sight").

Interested in hearing from others whether their experience is consistent with mine ... or not.

paul

RSX11M+

Veteran Member

- Joined

- Feb 14, 2011

- Messages

- 1,075

Yes, this describes a key which was made with a rotational offset....

3. Examining the notch-alignment around the circumference based on their positioning relative to the alignment-tab ("gun sight") it's clear that the new-key is notch-misaligned. I estimate that the notch-pattern is rotated roughly 20 degrees clockwise compared to the old-key. The old-key is pretty symmetrical; the new-key is rather asymmetrical as regards notch-position :-<..

This isn't a perfect depiction, but gives the idea:

Is this what you're seeing? (an offset)

I would think depth might also be an issue, but this offset is the killer.

AK6DN

Veteran Member

On my two XX2247 originals the notches are completely mirrored/symmetric around the gunsight. The fourth notch is directly at the bottom, 180deg opposite of the alignment gunsight.

Don

Don

Matlock

Experienced Member

I have a PDP-11/70 panel (technically a DEC Datasystem 570) that I am in the process of re-animating using Simh on a BeagleBone linux board. I am looking forward to seeing the RSX11M+ light pattern run on the 11/70 panel for the first time in many decades.

I don't have a key for it and actually don't need a key but I would love to have one for appearances. Does anyone know the code for a PDP-11/70 panel?

Thanks,

Mark

I don't have a key for it and actually don't need a key but I would love to have one for appearances. Does anyone know the code for a PDP-11/70 panel?

Thanks,

Mark

pbirkel@gmail.com

Veteran Member

Yes, this describes a key which was made with a rotational offset.

This isn't a perfect depiction, but gives the idea:

Is this what you're seeing? (an offset)

I would think depth might also be an issue, but this offset is the killer.

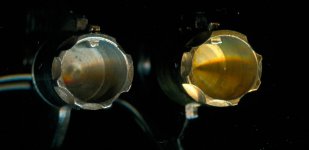

What I see qualifies as a Left Offset. In the photo below (open separately to see it at a decent size!), the original is on the left; the new key on the right. The shot is slightly angled so that you can also see the difference in notch-depth. The notch to the right is the one that barely exists on the original key.

RSX11M+

Veteran Member

- Joined

- Feb 14, 2011

- Messages

- 1,075

@Matlock - We don't know for sure yet - we need a member with an 11/70 to report in, or to try the key recipe on one.

@pbirkel@gmail.com - Am I to understand this was one of our trial keys from NF6X?

I think this may be a matter of practice and cutting machine adjustment. Compared to the original, the new key is slightly irregular, less "accurate" and perhaps unintentionally set to cut with "Left Offset". Outcome also depends on the "Master" key set, how carefully they were cut and possibly how "used" they are. Looking at the photo of the key cutting machine, it's use is not implicit.

I downloaded manuals for it from HPC, and it's actually a bit of an art to operate. I gather that model of the machine wasn't intended to cut a key from code, only to "duplicate". (hence the set of "masters")

Your photo is very helpful - thank you. Perhaps with it, the next attempt would be successful.

After seeing the manual for two fully capable key cutting machines, I am more convinced than ever that making these keys from our "Code" should work.

@pbirkel@gmail.com - Am I to understand this was one of our trial keys from NF6X?

- Agreed - left offset, should be Centered.

- I'm not sure what effect the extra cut-out depth will have. Looking at the copy, there's a score mark in the milled wall at about the correct depth. Could that be the point the key should be faced to?

- Finally, there appears to be considerable variation in the cut-out placement compared to the original. It's as if the cutting machine drifted from the intended positions slightly. There's less "land" between 7-6 than should be, and between 4-3 it's nearly nonexistent.

I think this may be a matter of practice and cutting machine adjustment. Compared to the original, the new key is slightly irregular, less "accurate" and perhaps unintentionally set to cut with "Left Offset". Outcome also depends on the "Master" key set, how carefully they were cut and possibly how "used" they are. Looking at the photo of the key cutting machine, it's use is not implicit.

I downloaded manuals for it from HPC, and it's actually a bit of an art to operate. I gather that model of the machine wasn't intended to cut a key from code, only to "duplicate". (hence the set of "masters")

Your photo is very helpful - thank you. Perhaps with it, the next attempt would be successful.

After seeing the manual for two fully capable key cutting machines, I am more convinced than ever that making these keys from our "Code" should work.

RSX11M+

Veteran Member

- Joined

- Feb 14, 2011

- Messages

- 1,075

PDP-11/05 and PDP-11/10 Key Blank Identified

PDP-11/05 and PDP-11/10 Key Blank Identified

I've made a little progress on the PDP-11/10 key.

The "Blank" which fits my PDP-11/10 can be found in the U.S. at Home Depot. It is made by The Hillman Group and is marketed as #80 AXXESS brand.

The blank is longer than required, so it doesn't seat fully in the cylinder until cut.

I will post again once I've determined a way to share the cut depths and positions. Presumably I'll have a working key by then myself.

Additional Note: The rack cabinet lock cylinder for this system requires a different blank.

PDP-11/05 and PDP-11/10 Key Blank Identified

I've made a little progress on the PDP-11/10 key.

The "Blank" which fits my PDP-11/10 can be found in the U.S. at Home Depot. It is made by The Hillman Group and is marketed as #80 AXXESS brand.

The blank is longer than required, so it doesn't seat fully in the cylinder until cut.

I will post again once I've determined a way to share the cut depths and positions. Presumably I'll have a working key by then myself.

Additional Note: The rack cabinet lock cylinder for this system requires a different blank.

RSX11M+

Veteran Member

- Joined

- Feb 14, 2011

- Messages

- 1,075

So here's an easy question for you holders of Original DEC XX2247 keys out there... what are the barrels made of?

I'm guessing they're all steel. Think you could verify this - maybe with a magnet test?

I see both Steel and Brass blanks are commonly available.

I'm guessing they're all steel. Think you could verify this - maybe with a magnet test?

I see both Steel and Brass blanks are commonly available.

pbirkel@gmail.com

Veteran Member

Yes, that's correct. The original key is steel; the new NF6X key is brass.

@pbirkel@gmail.com - Am I to understand this was one of our trial keys from NF6X?

AK6DN

Veteran Member

My original DEC XX2247 keys are all steel (pass the magnet test) and are prone to rusting.

The rustier one I have had in my possession for 35+ years. The other one came with a PDP-8m.

I also checked these keys function in my 11/70 and 11/60 consoles.

My recollection from working in DEC PDP-11 h/w engineering was XX2247 was the only key needed on my keyring for DEC systems (at least the commonly available blinky light console ones in the 70s/80s).

Don

The rustier one I have had in my possession for 35+ years. The other one came with a PDP-8m.

I also checked these keys function in my 11/70 and 11/60 consoles.

My recollection from working in DEC PDP-11 h/w engineering was XX2247 was the only key needed on my keyring for DEC systems (at least the commonly available blinky light console ones in the 70s/80s).

Don

Last edited:

RSX11M+

Veteran Member

- Joined

- Feb 14, 2011

- Messages

- 1,075

Updated Key List as of Oct 11, 2013

Updated Key List as of Oct 11, 2013

Confirmed ACE Keys and Uses:

Blade Keys:

We have confirmed that "Blade" type key blanks for PDP-11/05 and PDP-11/10 CPUs are commonly available in the U.S. at Home Depot as AXXESS #80. (Hillman Group) Cut dimensions to follow when confirmed.

Updated Key List as of Oct 11, 2013

Confirmed ACE Keys and Uses:

Code:

DEC# ACE CODE CPU

XX2247 7654321:5173757 PDP-8 (Classic)

XX2247 7654321:5173757 PDP-8/e

XX2247 7654321:5173757 PDP-8/I

XX2247 7654321:5173757 PDP-8/L (and expansion box)

XX2247 7654321:5173757 PDP-8/m

XX2247 7654321:5173757 PDP-11/20

XX2247 7654321:5173757 PDP-11/30

Plastic Un-Cut PDP-11/44 (any ACE key works)

XX2247 7654321:5173757 PDP-11/45

XX2247 7654321:5173757 PDP-11/60

XX2247 7654321:5173757 PDP-11/70

? 7654321:7557537 PDP-11/730 (VAX)

XX2247 7654321:5173757 PDP-11/750 (VAX)Blade Keys:

We have confirmed that "Blade" type key blanks for PDP-11/05 and PDP-11/10 CPUs are commonly available in the U.S. at Home Depot as AXXESS #80. (Hillman Group) Cut dimensions to follow when confirmed.

Last edited:

NF6X

Veteran Member

Hi, guys. I'm sorry I haven't been able to respond for a while.

My machine isn't too hard to use, but the machine itself does not enforce any particular "clocking" of the cuts. It just copies the angular positions of whatever original key is used. So, it appears that my depth and space set of keys that I got from eBay not only has the the wrong angular offset for these DEC keys, but also may not have the right depths. I'll need to dig them back out and measure the depths to see whether the depth keys are off, or I didn't seat the blank at the proper depth, or my touch wasn't quite right when I made the copies.

The wall widths between the cuts can vary a bit depending on the operator's touch, since there's a little bit of angular wiggle when pushing the original against the fixed pin that reads the cut depths. That shouldn't normally affect the key's operation as long as the cuts are close enough to the right angular offset, and the depths are right.

Without a set of depth keys with the right angular offset, I guess I'm not cutting this particular key by code. I'm sorry they didn't work!

My machine isn't too hard to use, but the machine itself does not enforce any particular "clocking" of the cuts. It just copies the angular positions of whatever original key is used. So, it appears that my depth and space set of keys that I got from eBay not only has the the wrong angular offset for these DEC keys, but also may not have the right depths. I'll need to dig them back out and measure the depths to see whether the depth keys are off, or I didn't seat the blank at the proper depth, or my touch wasn't quite right when I made the copies.

The wall widths between the cuts can vary a bit depending on the operator's touch, since there's a little bit of angular wiggle when pushing the original against the fixed pin that reads the cut depths. That shouldn't normally affect the key's operation as long as the cuts are close enough to the right angular offset, and the depths are right.

Without a set of depth keys with the right angular offset, I guess I'm not cutting this particular key by code. I'm sorry they didn't work!

NF6X

Veteran Member

I think it'll turn in to a wall of text if I try to explain how my machine works in text instead of a video. I'll cover some specific points that I was asked about, though.

The shaft that holds the blank and original keys is spring-loaded to force it away from the cutter. When it's fully away from the cutter (that is, whenever the operator isn't manually pushing it towards the cutter), there's a positive angular stop that keeps it in the "home" position. That lets the operator turn the clamping collar at the blank end of the shaft without the shaft turning.

Once the operator pushes the shaft towards the cutter, the shaft can be rotated freely. There are no positive stops for the angular positions of the cuts. The angular positions of the cuts are determined primarily by the cuts on the original, and secondarily by how much the operator wiggles the key angularly when making each cut.

The shaft that holds the blank and original keys is spring-loaded to force it away from the cutter. When it's fully away from the cutter (that is, whenever the operator isn't manually pushing it towards the cutter), there's a positive angular stop that keeps it in the "home" position. That lets the operator turn the clamping collar at the blank end of the shaft without the shaft turning.

Once the operator pushes the shaft towards the cutter, the shaft can be rotated freely. There are no positive stops for the angular positions of the cuts. The angular positions of the cuts are determined primarily by the cuts on the original, and secondarily by how much the operator wiggles the key angularly when making each cut.