Hi, what do you mean "No stiction on the heads or platters"? These drives use oxide media and twinarm heads, they are not susceptible to stiction like metallic media drives.

Regardless of media or heads, spindles and bearings fail, and rubber degrades. In this case, both the platters and head arms move freely on their bearings. Not so for other CMI drives I have worked on. Spindle stiction can affect nearly any hard drive of this age, especially if stored improperly, no?

What data do you intend to recover from a 30MB hard drive from 1984? If you are doing it "for fun," there is nothing of interest, and the likelihood of recovering valid information from a drive like this is exceptionally low. Unless you have the exact original controller it was paired with (Not "another WD," the specific card), it's contents will never be legible.

This drive is out of a custom NS32016-based system and contains an unusual copy of early BSD Genix. It was operational as recently as a couple of years ago. While many of the files

were able to be extracted while the drive was still running, critically, vmunix and other binaries were not, nor was a binary dump of the drive taken - meaning a working system cannot be assembled without additional data recovery, or cobbling together from other sources online.

It's not "just another WD", nor is it just from some old IBM PC with a copy of MS-DOS 3.30 and Alley Cat on it. And yes, I have the original controller, a NatSemi-rebranded SMS FWD8006 Multibus device (BLC-8232), with full schematics. (Scans coming.)

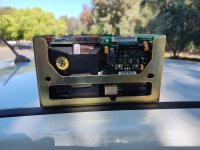

This behavior is related to a failure to locate the embedded track zero. It's possible that the glass interrupter wheel inside the optical feedback unit has been cracked, shattered, or otherwise misaligned with the shaft of the DC servo motor. You can attempt to open this and check, but without the original alignment equipment, it is unlikely that you will get it correct enough to actually read data - Though the drive may at least become operable after this, the heads probably will not line up with existing track data on the platters anyways.

Thankfully, the optical encoder disc is still in tact, and the optoelectronics are still functional. There is a factory-made groove showing the original alignment between shaft and encoder that implies neither has slipped, or if so, it's only by a step or two at most.

You can attempt to probe the head output test point and compare it with the waveforms posted here earlier, but I don't recall seeing one for the embedded track 0 position. Your drive probably has media rot and cannot locate it's track 0 marks on the disk, rendering it unusable.

The waveforms shown do seem to match, and with

@Al Kossow 's helpfully uploaded information, I understand the principle of operation and the expected approach for head alignment. At the moment I suspect a failed DG211, but I need more time in the lab to confirm, I was rushing through my last measurements yesterday before dinner. (I'm more used to 405x chips of this era failing, but all analog switch ICs from early 80s process nodes are susceptible to the same sorts of failures.)

I expect I'll be able to get

@djg 's device to work - I have been working with his devices for years now and have good experiences with them.

I have a good head start, thanks to the work of others.

@djg or

@Al Kossow 's work has been fundamental in recovering and emulating thousands of hard drives and machines at large, and hundreds of my own clients' drives and systems. Thank you for your time.

Does that matter? I haven't worked on a servo motor drive but it looks for DC servo motors is driven by a bipolar DC voltage which isn't that different from a voice coil. I don't see the power amp in the schematic. Is that off board? Looks like there is an op amp chain from the encoder that you can inject an offset into which should shift the head position like I did with voice coil.

Hey David! The power amp is indeed on a second board. I can draw mine up later today if it'd help, but it's about what you'd expect.

You're right about injecting an offset. After the initial track zero hunt fails, the drive locks the head, asserts write fault, and refuses to obey any further commands. I can override the head lock (remove or disable the solenoid) and work out a means to inject an appropriate control signal. Happy to take this to your mailing list for further work!

Sorry, I had forgotten the details. Commercial recovery services actually built external motor controllers that would plug onto the bowl, and their own read chain

re. embedded servos from another comment. They also used commercial spin stands from companies like Guzik

https://www.guzik.com/products/head-and-media-disk-drive-test/spinstands/

Earlier servo controlled actuators used a separate platter for the servo tracks. Embedded came later. Most drives do not have optical coarse position sensors,

the info all comes from the platter.

I went down a research rathole late last year.

Lots of fun evolution during the 90s described in papers on

http://bitsavers.org/pdf/santaClaraUniversity/IIST/ and I acquired a bunch of internal

drive vendor documentation around then as well that I uploaded under the vendor's directories.

Thanks Al! Sadly the local shop that had a full rig for this junked their gear a few years back; they weren't getting as much call for it and needed the space back. I wish I'd known, I would have rescued it! A local musician looking to recover data from a synthesizer's hard drive ended up having more success with David's design than with that group.