kishy

Veteran Member

I have an irritating, probably easy to fix problem with two "previous homeowner installed" light fixtures in a closet that merges with the crawlspace. This closet/crawlspace is where my computer stuff lives so this problem will come back to bite me if not corrected soon (I need to be able to see in there).

The symptom: the two 60W incandescent lightbulbs do not fully light up. The one closer to the supply line is roughly half as bright as it should be and the next bulb is about half as bright as the first. CFL's flicker and don't give off any useful light. If two non-matching incandescent bulbs are used inconsistent results can happen (which bulb is brighter will switch back and forth).

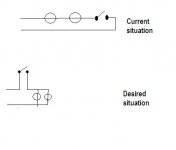

The problem: the two bulbs are wired in series.

I know what needs to be done to fix this...put the bulbs in parallel and then the [(set of two bulbs in parallel) in series with the switch]

However, one bulb and the switch just so happen to be encased in a finished wall. If I had to venture a guess I'd say the exposed lightbulb socket was probably placed in a pre-existing junction box (and just had the lid removed to put the light in it) and the circuit was fine before that was done. That's just a guess though.

The easy solution would be to take out the light socket in the finished wall and just jump the wires together, but it's nice having light in that particular spot (however if I had to pick only one, I would sacrifice this one).

Although I really don't think it's possible, does anyone see a way I can do this without ripping up the wall and without removing the second lightbulb socket?

Also while I'm at it, which wire is supposed to be switched...white or black?

The symptom: the two 60W incandescent lightbulbs do not fully light up. The one closer to the supply line is roughly half as bright as it should be and the next bulb is about half as bright as the first. CFL's flicker and don't give off any useful light. If two non-matching incandescent bulbs are used inconsistent results can happen (which bulb is brighter will switch back and forth).

The problem: the two bulbs are wired in series.

I know what needs to be done to fix this...put the bulbs in parallel and then the [(set of two bulbs in parallel) in series with the switch]

However, one bulb and the switch just so happen to be encased in a finished wall. If I had to venture a guess I'd say the exposed lightbulb socket was probably placed in a pre-existing junction box (and just had the lid removed to put the light in it) and the circuit was fine before that was done. That's just a guess though.

The easy solution would be to take out the light socket in the finished wall and just jump the wires together, but it's nice having light in that particular spot (however if I had to pick only one, I would sacrifice this one).

Although I really don't think it's possible, does anyone see a way I can do this without ripping up the wall and without removing the second lightbulb socket?

Also while I'm at it, which wire is supposed to be switched...white or black?