Here are my results from trying the new 'White King Oxy-Lift liquid gel'

I had four items under test:

2x computer drive bay covers, both identically yellowed.

1x A1060 Sidecar front panel, very slightly yellowed.

1x VIC-20 top panel, moderately yellowed.

As I was unsure if the new gel contained TAED, I decided to use the two identical covers as a comparision of the gel with and without TAED.

One panel was treated with the gel straight from the bottle. For the other panel, and all other items, I mixed 1 teaspoon of laundry whitener powder in 1 teaspoon of water in an old teacup. Then I added the gel until the cup was half full. I used two separate paint brushes to apply the gel to the items to avoid mixing. Incidentally, the gel is a clear light blue colour. Apart from the colour, it looks and feels very much like a 'personal lubricant' <ahem>

The items were all put out at 11:00 AM on a hot, sunny day. Temperature was 31C. Due to the hot, dry conditions, I found I had to reapply the gel every 5-10 minutes to avoid it drying out. I must confess it was a bit of a chore.

At 1:00PM the items looked ready, so I brought them in. By then the temperature was 33C. The items were rinsed and cleaned, and the masking tape I used to blank off areas for comparison was removed.

The results:

The computer blanking plates:

Unfortunately the masking tape did not do its job very well, but the comparison of treated and untreated areas can still be easily seen. Its interesting to note that the gel appears to work just as well without the added laundry booster, so either the gel already contains TAED, or, the Aussie sun is so strong it works just as well without.

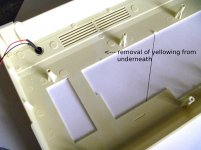

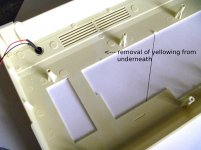

The VIC-20 case:

For comparison purposes, this was treated on the right hand side only. The plastic appears to be the same as in the other VIC case I tried last time, except that the yellowing was not as bad. Nearly all the yellowing was gone after the 2 hour treatment. There were no signs of 'blooming'. One interesting thing I noted was that this VIC case was slightly yellowed underneath, something I did not notice until I rinsed it afterwards, and noticed that some of the gel had run inside. Even though there was little sunlight there, the gel still removed this slight yellowing. See below:

I did not take pics of the A1060 Sidecar front as it was very slightly yellowed and the comparison would have been hard to see. What yellowing that was there was removed, and there was no blooming.

From the results here, I consider the gel to be successful, and an ideal substitute for the brush-on version of Retr0brite.

My personal preference is still for submerging the item in a bath of dissolved laundry whitener, due mainly to the nuisance of having to reapply so often during a hot Aussie day. However, it is a good method for large items, or on a cooler day.

Oh...and I almost forgot. The old teacup, which was heavily stained with tea residue, and was almost impossible to clean, is now sparkling clean!