Scott Kevill

Experienced Member

I've rescued a TRS-80 Model III that has been in someone's shed for at least the last 20 years. Aside from the four mice skeletons I found inside it, the video has some issues:

I haven't done any work with CRTs before, but this looked like a problem with the vertical deflection. The text should be at the top of the screen but instead starts at the centre. The actual text was flickering fairly rapidly, and of course the mushed up dots in the centre shouldn't be there. The intensity of those match the text below them.

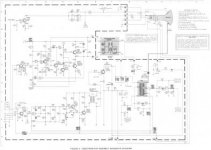

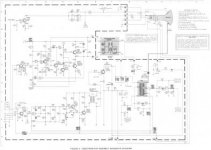

So I looked over the schematic from the Model III Technical Reference Manual (in particular the "TOP VERTICAL OUTPUT" section) and the voltages were quite a bit different. The supply voltages were fine though.

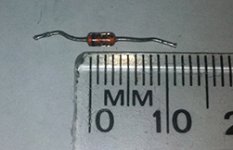

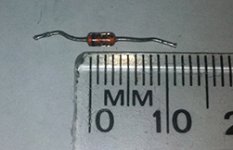

Now the interesting part was the voltage drop across the diode CR609 was 0.1V. Aren't diodes supposed to have a voltage drop of at least 0.7V? CR610 was listed as an identical stock number and it had a voltage drop of 1.6V (if I remember correctly) which was a red flag. Unfortunately the replacement part list doesn't specify any details about the diode other than it is "silicon". I de-soldered it so that I could read any info from the diode itself, and it has A24 on one side, and 031 on the other side. A little hard to see from the photos, but you can make it out:

I couldn't find any useful information with Google from this info. Any ideas? And am I on the right track?

I haven't done any work with CRTs before, but this looked like a problem with the vertical deflection. The text should be at the top of the screen but instead starts at the centre. The actual text was flickering fairly rapidly, and of course the mushed up dots in the centre shouldn't be there. The intensity of those match the text below them.

So I looked over the schematic from the Model III Technical Reference Manual (in particular the "TOP VERTICAL OUTPUT" section) and the voltages were quite a bit different. The supply voltages were fine though.

Now the interesting part was the voltage drop across the diode CR609 was 0.1V. Aren't diodes supposed to have a voltage drop of at least 0.7V? CR610 was listed as an identical stock number and it had a voltage drop of 1.6V (if I remember correctly) which was a red flag. Unfortunately the replacement part list doesn't specify any details about the diode other than it is "silicon". I de-soldered it so that I could read any info from the diode itself, and it has A24 on one side, and 031 on the other side. A little hard to see from the photos, but you can make it out:

I couldn't find any useful information with Google from this info. Any ideas? And am I on the right track?