modem7

10k Member

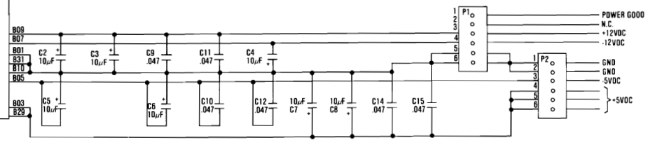

Information:What is the Power Good reading now ?, With nothing connected to the PSU, Previously it was way too high,

- A TTL gate cannot generate a logic HIGH of +15V, and so that was sure to be a miss-measurement.

- The POWER GOOD signal generated by the PSU is not used at all in the 5162.

- Seeing the POWER GOOD signal at crudely +5V (a TTL logic HIGH) would inform the user that the PSU believes that 'all is well'.

... With nothing connected to the PSU ...

In the photo, it looks like the system board is still being connected to the PSU, either via P8 or P9 (the photo resolution doesn't allow me to make the determination).13.6 mV

If so, we know from post #36, that with either P8 or P9 connected, that one or more voltages on P10 go 'missing in action', and accordingly, we would expect the POWER GOOD signal to go to a TTL LOW level.

And with just the hard drive plugged in ? and does it spin up fully

If the hard drive was plugged into the PSU at post #38, then the 'nothing' that Malc asked for was not met.Yes the hard drive was plugged in and it does sound like it spins up completely.