Maikudou

Experienced Member

Hi, I have a 8513-001 monitor (S/N 72-0182100).

It works good, no burn-in, good converjence and focus, except the raster is too narow (to my taste, Maintenance manual says "at least 20cm", and it is exaclty 20cm max). The adjustment coil can be turned to make it even narrower, but not wider. It is like an inch less than the bezel width each side.

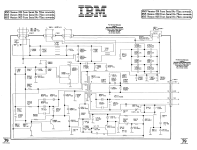

I learned the width is controlled by the coil _and_ some capacitors adjacent to it. I've measured every one close enough (I have the schematic from the web as well as troubleshooting guides which are googleable, I know about them, thanks) and they have good capacitance, but ESRs I am not that sure, for caps 225 0.22uF and 226 0.16uF (closest PP ones to the coil per schematic) the cheap ESR meter from Amazon says its ok, around 3.7 Ohm, "good", but I don't believe it, it measures 80 Ohm for 0.01uF, "bad", for new one fresh out of Mouser, which might not be true, probably it can't measure small capacitance cap reliably, it says either overload or 'bad" for anything smaller that 0.1 uF, I think. In and out of circuit.

The troubleshooting guide from the web suggests when having "width problems" suspect a couple of resistors (R305, R306) close to some chip, which I think unlikely? How often do 1/2W resistor fail anyway? And they measure to spec in-curcuit.

Did anyone succesfully fixed the width problem in this or similar monitors. I can replace all of the caps, but there are _a lot_, and I don't really want to cut the CRT PCB from the goo it is fixed with to put the main PCB out.

Also sides of the raster are not uniformly flat or uniformly pincushioned either way, it starts slightly wider, then arches to slightly narrower than back, almost like very narrow (1/8'') S shape, does it suggest what else can be at fault?

Thanks!

It works good, no burn-in, good converjence and focus, except the raster is too narow (to my taste, Maintenance manual says "at least 20cm", and it is exaclty 20cm max). The adjustment coil can be turned to make it even narrower, but not wider. It is like an inch less than the bezel width each side.

I learned the width is controlled by the coil _and_ some capacitors adjacent to it. I've measured every one close enough (I have the schematic from the web as well as troubleshooting guides which are googleable, I know about them, thanks) and they have good capacitance, but ESRs I am not that sure, for caps 225 0.22uF and 226 0.16uF (closest PP ones to the coil per schematic) the cheap ESR meter from Amazon says its ok, around 3.7 Ohm, "good", but I don't believe it, it measures 80 Ohm for 0.01uF, "bad", for new one fresh out of Mouser, which might not be true, probably it can't measure small capacitance cap reliably, it says either overload or 'bad" for anything smaller that 0.1 uF, I think. In and out of circuit.

The troubleshooting guide from the web suggests when having "width problems" suspect a couple of resistors (R305, R306) close to some chip, which I think unlikely? How often do 1/2W resistor fail anyway? And they measure to spec in-curcuit.

Did anyone succesfully fixed the width problem in this or similar monitors. I can replace all of the caps, but there are _a lot_, and I don't really want to cut the CRT PCB from the goo it is fixed with to put the main PCB out.

Also sides of the raster are not uniformly flat or uniformly pincushioned either way, it starts slightly wider, then arches to slightly narrower than back, almost like very narrow (1/8'') S shape, does it suggest what else can be at fault?

Thanks!

Last edited: