Endersending

Experienced Member

I need some advice for a problem I am having. I have an 8" Floppy drive that gives me read after write errors when using DS/DD disks.

I have followed instructions on setting up the 16FDC to accept Shugart drives.

my drive setup:

A: 5.25 half height floppy

B: 5.25 Gotek

C: 8" Shugart 850/851 (the drive I have been tinkering with so may be out of alignment we won't worry about this one right now)

D: 8" Shugart 850/851 <-- This one gives read after write errors for DS/DD.

I have been testing with really nice condition Dyson DS/DD Floppies or a Wabash Single Sided.

Using CDOS I can INIT (format) Double Sided Double Density DS/DD.

Trying to WRTSYS or XFER gives me read after write errors.

The 8" drive can INIT and XFER fine with all other formats.

Trying to copy using RDOS gives errors 30 and 34 (CRC)

The 5.25 drives can use all formats, no problems.

Why can the 8" drive work with single sided double density, and double sided single density, but not ds/dd?

Is this a Shugart drive problem or a 16FDC problem?

Any recommendations on testing I can do or ideas about the problem would be helpful.

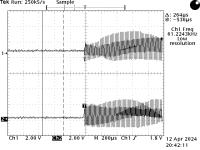

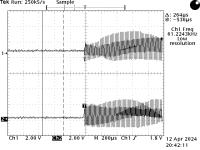

Attached is a scope reading from drive C: both heads test points 1 and 2:

Left side is read signal, right side is write signal.

Read signal is about 130Mv (which the manual says is nominal)

I have followed instructions on setting up the 16FDC to accept Shugart drives.

my drive setup:

A: 5.25 half height floppy

B: 5.25 Gotek

C: 8" Shugart 850/851 (the drive I have been tinkering with so may be out of alignment we won't worry about this one right now)

D: 8" Shugart 850/851 <-- This one gives read after write errors for DS/DD.

I have been testing with really nice condition Dyson DS/DD Floppies or a Wabash Single Sided.

Using CDOS I can INIT (format) Double Sided Double Density DS/DD.

Trying to WRTSYS or XFER gives me read after write errors.

The 8" drive can INIT and XFER fine with all other formats.

Trying to copy using RDOS gives errors 30 and 34 (CRC)

The 5.25 drives can use all formats, no problems.

Why can the 8" drive work with single sided double density, and double sided single density, but not ds/dd?

Is this a Shugart drive problem or a 16FDC problem?

Any recommendations on testing I can do or ideas about the problem would be helpful.

Attached is a scope reading from drive C: both heads test points 1 and 2:

Left side is read signal, right side is write signal.

Read signal is about 130Mv (which the manual says is nominal)