Creideiki

Member

Hello again peoples.

I've recently come across a KSR-33 teletype that my university was discarding (I've switched schools by the by, I'm at Brock University now, not the University of Waterloo). The teletype doesn't have a dialer or anything in it, so it was most definitely used either as a dumb terminal for a mini or something.

Cosmetically, the upper portions of the teletype are quite perfect - just a few scuffs and some dirt and grime that is older then I am - the base though does show a bit of rust, so that'll need some attention.

Smoke testing the teletype (not my idea as a first test, but that was done by the electronics shop), shows that it powers up fine, and looks to be functional in most regards. However there is a major issue - though I think I know the solution to that - namely, the carriage stays in one position and is repeatedly striking the print head against the paper. (It does not respond to any character input, nor does it print anything, as there is no ink ribbon.)

The solution to that problem I believe is that several of the cables that extend from the back of the teletype are not connected to anything, and there is a large box (branded by a company called UTEC, or some such) that has what appears to be the sockets for those plugs.

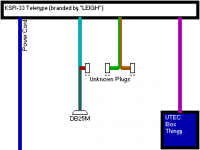

Here's an illustration of the wiring:

The unknown plugs-that-do-something-which-I-don't-know-what-that-is match up to three sockets on the UTEC box-thingy. So I'll assume the cables plug into the UTEC box-thing. I am also assuming that the teletype is converted for RS-232 signalling (as evidenced by the DB25M connector.

The major problem is that I think the UTEC box is the RS232 converter, and should be controlling what the TTY is doing, and that without the plugs inserted the teletype becomes a non-responsive paperweight.

Here's a link to a (blurry) photo of my KSR-33 on the floor of my dorm room: > Click me! <

Unfortunately, I won't be able to do anything with it until Sunday evening or Monday, as I'm home for the weekend. (Also, I'd like to know if I should try plugging the various cables into the UTEC box-thingy, or whether that would be unwise and could damage the teleprinter.)

So, any helpful hints/suggestions? And what all have you people done with your KSR-33s? (Other then the blindingly obvious uses of course.)

I've recently come across a KSR-33 teletype that my university was discarding (I've switched schools by the by, I'm at Brock University now, not the University of Waterloo). The teletype doesn't have a dialer or anything in it, so it was most definitely used either as a dumb terminal for a mini or something.

Cosmetically, the upper portions of the teletype are quite perfect - just a few scuffs and some dirt and grime that is older then I am - the base though does show a bit of rust, so that'll need some attention.

Smoke testing the teletype (not my idea as a first test, but that was done by the electronics shop), shows that it powers up fine, and looks to be functional in most regards. However there is a major issue - though I think I know the solution to that - namely, the carriage stays in one position and is repeatedly striking the print head against the paper. (It does not respond to any character input, nor does it print anything, as there is no ink ribbon.)

The solution to that problem I believe is that several of the cables that extend from the back of the teletype are not connected to anything, and there is a large box (branded by a company called UTEC, or some such) that has what appears to be the sockets for those plugs.

Here's an illustration of the wiring:

The unknown plugs-that-do-something-which-I-don't-know-what-that-is match up to three sockets on the UTEC box-thingy. So I'll assume the cables plug into the UTEC box-thing. I am also assuming that the teletype is converted for RS-232 signalling (as evidenced by the DB25M connector.

The major problem is that I think the UTEC box is the RS232 converter, and should be controlling what the TTY is doing, and that without the plugs inserted the teletype becomes a non-responsive paperweight.

Here's a link to a (blurry) photo of my KSR-33 on the floor of my dorm room: > Click me! <

Unfortunately, I won't be able to do anything with it until Sunday evening or Monday, as I'm home for the weekend. (Also, I'd like to know if I should try plugging the various cables into the UTEC box-thingy, or whether that would be unwise and could damage the teleprinter.)

So, any helpful hints/suggestions? And what all have you people done with your KSR-33s? (Other then the blindingly obvious uses of course.)

Last edited: