Success! Reading the threads linked in my previous post gave me an idea.

For one, I left the stupid tiny spring + plastic piece out that allows people to snap the sleeve in the first place. It is 100x easier to assemble the latch mechanism without that pointless part in there, and now curious fingers are less likely to destroy the drive.

Here is how I reassembled and fixed it:

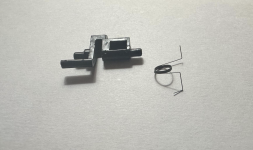

I put the medium sized spring on the metal shaft so that it could hook onto the sleeve as intended (watch the orientation).

I slid the broken sleeve onto the shaft and turned it around until the notch was aligned (you can tell because the crack will close up).

I then got a length of 30awg wire-wrapping wire , stripped the insulation off of it, wrapped it around the plastic sleeve as tightly as I could (it wasn't "tight"... it's just too fiddly for my fingers), put a small vice grip on it in such a way that it would both close the crack\gap on the broken sleeve and hold the end of the wire in place.

Then I used a soldering iron (Hakko set to ~680F) to both melt the cracks that were exposed AND to heat the wire so that it would embed itself into the plastic. I went all around the sleeve doing this. I didn't go too crazy with the iron since I don't have more plastic to "add" to bury the wire properly, but overall the wire is definitely pretty well embedded into the plastic. I found several other cracks in the plastic and melted those over.

I'm not sure if the sleeve is as strong as it would have been originally, but again... without the lock in place to create huge stresses on this part, it may actually hold up to normal use. I also added a tiny bit of oil to the surface (nub?) on the sleeve so that it could latch with a little less friction.

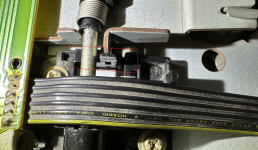

After this, put the large spring on the end of the shaft, lay the circuit board + ribbon cable and mounting system back in place, check to make sure the springs are all laying properly, reinsert the screws, hook the upper part of the large spring on the tensioning-hook, and that should be it.

I'm happy to say that the drive now latches securely and reads perfectly. It even read the first disk I put in it without errors. Additionally, it can be latched without a disk inserted now. I wouldn't necessarily recommend doing this all the time because it was never intended to do this, but at least now it won't cause the internal parts to instantaneously detonate.

I have attached pictures of the repairs as well as the spring placement.