shank

Experienced Member

Some early notes on a Model 16 renovation.... resurrection? A little of both, I guess.

A friend had this sitting in his storage shed in Fort Worth and he'd bought it moons ago when it was surplussed from CPE, Computer Product Engineering. I was surprised he still had it! I'd had a rental storage shed full of these old machines, though they weren't so old back then, but who knew anyone would actually want them or that I might as well? Alas. That's the confession part of this thread and as I stand before you today I hang my head in shame. Please don't ask me what I did with them. I'll lie if you do.

First question was how to ship it to the northwest and have it arrive intact. Answer is -- you can't, unless you disassemble it and then ship it. We decided to remove the drives and cards and ship them in separate boxes. Then the shell of the M16 was packed well to keep the CRT in position and the case from breaking. A week later the boxes showed up and everything arrived in fine shape.

The box under the table holds 2 15 Meg Hard Drive cases. Be awhile before I get to those. No bubbles shipped, but I have ST506 bubbles in storage--not that I expect they'll work.

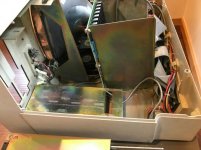

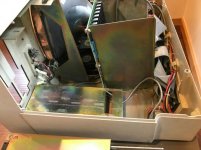

Quick look inside:

Right off the bat there's a problem and it might be a show stopper....

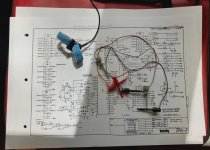

When I unpacked the M16 case I found a bit of metal that looked very familiar in the bottom of the box. Couldn't place it, but I kept it fortunately. It's the ferrite part of the flyback transformer on this Motorola video board. Somehow the brass rod broke releasing the ferrite in transit where it broke into 3 pieces. They're clean breaks and I have them all. I should be able to superglue it back together, replace it on the transformer and solder the brass rod back together. Ought to work fine. Close call!!

The cards are amazingly clean and most, maybe all from a quick look are very late revisions. That's a double edged sword, but they're clean and the only problem I found on visual inspection was a PAL hanging half way out of a socket. Looked to me like it had never been fully inserted.

Before anyone asks--I did not receive the Arcnet card. I have a box of boards somewhere and I might have one with those...

Otherwise, the unit, though intact other than the flyback, is filthy. I don't see mouse droppings, but I see a lot of dirt and dead bugs. First thing is to clean it up. I won't even attempt to fire it up until i change the 3 usual caps on the 11082 supply, clean it all up, put it back together, go through the 2 drives.... And then I'll see what happens. Oh, and I had to order a very long handled 1/4" nut driver. Can't work on one of these without one of those.

A friend had this sitting in his storage shed in Fort Worth and he'd bought it moons ago when it was surplussed from CPE, Computer Product Engineering. I was surprised he still had it! I'd had a rental storage shed full of these old machines, though they weren't so old back then, but who knew anyone would actually want them or that I might as well? Alas. That's the confession part of this thread and as I stand before you today I hang my head in shame. Please don't ask me what I did with them. I'll lie if you do.

First question was how to ship it to the northwest and have it arrive intact. Answer is -- you can't, unless you disassemble it and then ship it. We decided to remove the drives and cards and ship them in separate boxes. Then the shell of the M16 was packed well to keep the CRT in position and the case from breaking. A week later the boxes showed up and everything arrived in fine shape.

The box under the table holds 2 15 Meg Hard Drive cases. Be awhile before I get to those. No bubbles shipped, but I have ST506 bubbles in storage--not that I expect they'll work.

Quick look inside:

Right off the bat there's a problem and it might be a show stopper....

When I unpacked the M16 case I found a bit of metal that looked very familiar in the bottom of the box. Couldn't place it, but I kept it fortunately. It's the ferrite part of the flyback transformer on this Motorola video board. Somehow the brass rod broke releasing the ferrite in transit where it broke into 3 pieces. They're clean breaks and I have them all. I should be able to superglue it back together, replace it on the transformer and solder the brass rod back together. Ought to work fine. Close call!!

The cards are amazingly clean and most, maybe all from a quick look are very late revisions. That's a double edged sword, but they're clean and the only problem I found on visual inspection was a PAL hanging half way out of a socket. Looked to me like it had never been fully inserted.

Before anyone asks--I did not receive the Arcnet card. I have a box of boards somewhere and I might have one with those...

Otherwise, the unit, though intact other than the flyback, is filthy. I don't see mouse droppings, but I see a lot of dirt and dead bugs. First thing is to clean it up. I won't even attempt to fire it up until i change the 3 usual caps on the 11082 supply, clean it all up, put it back together, go through the 2 drives.... And then I'll see what happens. Oh, and I had to order a very long handled 1/4" nut driver. Can't work on one of these without one of those.