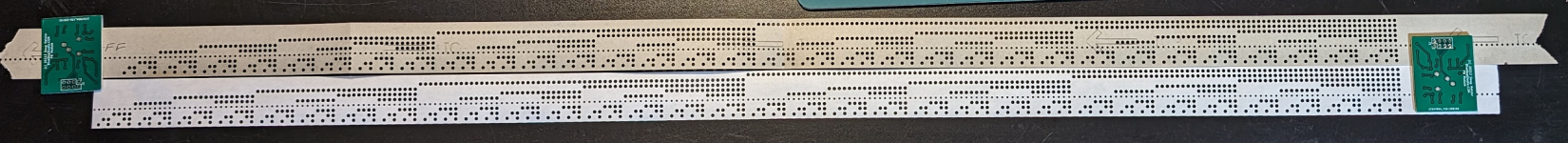

AHHH this is fantastic! Serendipity, maybe because of this thread-- I've been doing some similar stuff (but not yet as extensive!). I can't wait to check out your projects. I'm doing a short online session for the

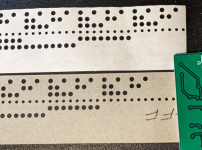

Typographics conference next week with some of my own stuff and I'll be delighted to speak to your work as well. I also ported Kare's Chicago (an all time favorite) to punch tape.

Here is my font.h as well if it will help you, though font creation was graph paper and a pencil

int letters[ 95 ][ 5 ] =

{

{ 0, 0, 191, 0, 0 }, // ! g

{ 0, 0, 0, 0, 0 }, // " // this will fail your "not mapped" test

{ 80, 248, 80, 248, 80 }, // # g

{ 0, 0, 0, 0, 0 }, // $

{ 0, 0, 0, 0, 0 }, // %

{ 0, 0, 0, 0, 0 }, // &

{ 0, 0, 14, 0, 0 }, // ' g

{ 0, 56, 68, 130, 0 }, // ( g

{ 0, 130, 68, 56, 0 }, // ) g

{ 0, 0, 0, 0, 0 }, // * 10

{ 0, 16, 56, 16, 0 }, // + g

{ 0, 128, 96, 0, 0 }, // , g

{ 0, 16, 16, 16, 0 }, // - g

{ 0, 192, 192, 0, 0 }, // . g

{ 0, 192, 56, 6, 0 }, // / g

{ 124, 162, 146, 138, 124 }, // 0 GOOD

{ 0, 132, 254, 128, 0 }, // 1 GOOD

{ 132, 194, 162, 146, 140 }, // 2 GOOD

{ 68, 130, 146, 146, 108 }, // 3 GOOD

{ 48, 40, 36, 254, 32 }, // 4 GOOD

{ 78, 146, 146, 146, 98 }, // 5 GOOD

{ 124, 146, 146, 146, 100 }, // 6 GOOD

{ 2, 226, 18, 10, 6 }, // 7 GOOD

{ 108, 146, 146, 146, 108 }, // 8 GOOD

{ 12, 146, 146, 146, 124 }, // 9 GOOD

{ 0, 0, 40, 0, 0 }, // : g

{ 0, 64, 40, 0, 0 }, // ; g

{ 8, 20, 34, 33, 0 }, // <

{ 0, 20, 20, 20, 0 }, // =

{ 0, 33, 34, 20, 8 }, // >

{ 2, 5, 89, 1, 2 }, // ?

{ 0, 0, 0, 0, 0 }, // @

{ 248, 20, 18, 20, 248 }, // A GOOD

{ 254, 146, 146, 146, 108 }, // B GOOD

{ 124, 130, 130, 130, 68 }, // C GOOD

{ 254, 130, 130, 130, 124 }, // D GOOD

{ 254, 146, 146, 146, 130 }, // E GOOD

{ 254, 18, 18, 18, 2 }, // F GOOD

{ 124, 130, 130, 146, 116 }, // G GOOD

{ 254, 16, 16, 16, 254 }, // H GOOD 40

{ 130, 130, 254, 130, 130 }, // I GOOD

{ 66, 130, 130, 126, 2 }, // J GOOD

{ 254, 16, 40, 68, 130 }, // K GOOD

{ 254, 128, 128, 128, 128 }, // L GOOD

{ 254, 12, 24, 12, 254 }, // M GOOD

{ 254, 8, 16, 32, 254 }, // N GOOD

{ 254, 130, 130, 130, 254 }, // O GOOD

{ 254, 18, 18, 18, 12 }, // P GOOD

{ 124, 130, 162, 66, 188 }, // Q GOOD

{ 254, 18, 50, 82, 140 }, // R GOOD 50

{ 140, 146, 146, 146, 98 }, // S GOOD

{ 2, 2, 254, 2, 2 }, // T GOOD

{ 126, 128, 128, 128, 126 }, // U GOOD

{ 14, 56, 224, 56, 14 }, // V GOOD

{ 62, 224, 56, 224, 62 }, // W GOOD

{ 198, 40, 16, 40, 198 }, // X GOOD

{ 6, 8, 240, 8, 6 }, // Y GOOD

{ 194, 162, 146, 138, 134 }, // Z GOOD 59

{ 0, 127, 65, 65, 0 }, // [ 60

{ 0, 0, 0, 0, 0 }, // \

{ 0, 65, 65, 127, 0 }, // ]

{ 0, 0, 0, 0, 0 }, // ^

{ 0, 0, 0, 0, 0 }, // _,

{ 0, 0, 0, 0, 0 }, // `

{ 0, 0, 0, 0, 0 }, // no frickin' clue!!

{ 64, 168, 168, 168, 112 }, // a

{ 252, 144, 144, 144, 96 }, // b GOOD

{ 112, 136, 136, 136, 136 }, // c GOOD

{ 96, 144, 144, 160, 252 }, // d GOOD

{ 112, 168, 168, 168, 48 }, // e GOOD

{ 32, 248, 36, 36, 0 }, // f GOOD

{ 24, 164, 164, 168, 124 }, // g GOOD

{ 252, 32, 16, 16, 224 }, // h GOOD

{ 0, 0, 244, 0, 0 }, // i GOOD

{ 0, 128, 116, 0, 0 }, // j GOOD

{ 252, 32, 80, 136, 0 }, // k GOOD

{ 0, 0, 124, 128, 0 }, // l GOOD

{ 240, 16, 224, 16, 224 }, // m GOOD

{ 248, 16, 8, 8, 240 }, // n GOOD

{ 112, 136, 136, 136, 112 }, // o GOOD 80

{ 252, 36, 36, 24, 0 }, // p GOOD

{ 24, 36, 36, 24, 252 }, // q GOOD

{ 0, 252, 16, 8, 16 }, // r GOOD

{ 144, 168, 168, 72, 0 }, // s GOOD

{ 0, 8, 124, 136, 0 }, // t GOOD

{ 120, 128, 128, 128, 120 }, // u GOOD

{ 56, 64, 128, 64, 56 }, // v GOOD

{ 56, 192, 56, 192, 56 }, // w GOOD

{ 136, 80, 32, 80, 136 }, // x GOOD

{ 140, 80, 32, 16, 12 }, // y GOOD 90

{ 136, 200, 168, 152, 136 }, // z GOOD

{ 0, 0, 0, 0, 0 }, // {

{ 0, 0, 0, 0, 0 }, // |

{ 0, 0, 0, 0, 0 }, // }

{ 0, 0, 0, 0, 0 }, // ~,