Paralel

Experienced Member

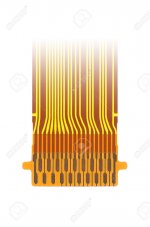

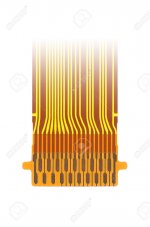

I have one of those awful orange, semi-transparent flat ribbon cables that were used for interfacing hard drives and floppy drives back in the early 90's laptops. Looks like this:

The damn thing tore on me, and I'll be damned if I can think of anyway to repair the stupid thing. I'm hoping someone else has run across this before and knows of a way to fix it. Unfortunately, it happens to be a custom cable for a laptop, and the laptop itself happens to be a rather uncommon model, so buying another one just isn't an option.

The damn thing tore on me, and I'll be damned if I can think of anyway to repair the stupid thing. I'm hoping someone else has run across this before and knows of a way to fix it. Unfortunately, it happens to be a custom cable for a laptop, and the laptop itself happens to be a rather uncommon model, so buying another one just isn't an option.