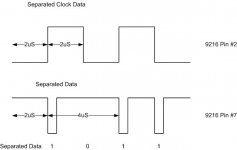

I've been reading about the 3740 IBM Format and have found that there are four difference address marks. The FDC detects these address marks because certain data cells will not have clock bits in them. All other data cells will have clock bits. The address marks are

1. Index Address Mark, there is only one of these marks on a track. It comes right after the index hole and preamble gap.

2. ID Address Mark, each sector has one. The track and sector numbers and checksum follow the ID mark.

3. DATA Address Mark, each sector has one. The actual data and checksums follow the DATA Address mark.

4. DELETED DATA, don't know much about this.

The 8272 status register ST1, bit zero, is called "Missing Address Mark" apparently if the FDC can read either the ID or DATA address mark this bit is set.

The 8272 status register ST1, bit two, is called "Sector not found error" I'm guessing here, but I think that maybe the ID and DATA address marks were found, but the actual sector number after the ID Address Mark was not found.

Again I'm guessing here, but I think that the Missing Address Mark error is a more basic error and the Sector not found is not. Meaning the if the sector not found occurs at least the address marks were read.

Is my thinking right here? Mike.