Lorne

Veteran Member

XANTHAN GUM & BRUSH ON TECHNIQUE

Mixed ½ pint of H2O2 solution with 1/8 tsp of Oxy powder, and stirred to dissolve Oxy.

Added ¼ tsp of Xanthan Gum and stirred. The Xanthan Gum didn’t want to dissolve and instead coagulated.

Left it for 15 mins – still the same.

Added another ¼ tsp, and stirred some more.

Still coagulated.

Beginning to have doubts about the success of this method.

Left it ½ hour, and it changed consistency to a foam, floating on top of a liquid.

Another ½ hour and it’s now a foamy bubbly gel type of mixture.

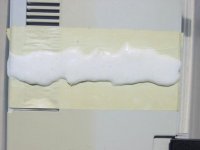

Put masking tape on the test piece to outline a test area.

And then applied a thin coating of the XG mixture.

Continued in next reply (ie: max 5 attachments per reply).

Mixed ½ pint of H2O2 solution with 1/8 tsp of Oxy powder, and stirred to dissolve Oxy.

Added ¼ tsp of Xanthan Gum and stirred. The Xanthan Gum didn’t want to dissolve and instead coagulated.

Left it for 15 mins – still the same.

Added another ¼ tsp, and stirred some more.

Still coagulated.

Beginning to have doubts about the success of this method.

Left it ½ hour, and it changed consistency to a foam, floating on top of a liquid.

Another ½ hour and it’s now a foamy bubbly gel type of mixture.

Put masking tape on the test piece to outline a test area.

And then applied a thin coating of the XG mixture.

Continued in next reply (ie: max 5 attachments per reply).