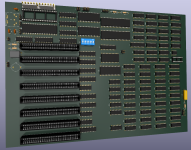

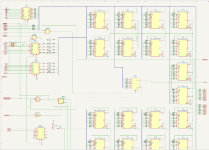

Hello fellow retro computer fans! I want to share my recent project progress and ask for a little help. I have been looking for an IBM PC 5160 for several years, but the prices for them are off the charts where I live, so I kind of gave up on it. Until a couple of weeks ago, when I stumbled upon the recreation project for the original IBM CGA video card by hkzlab. He did a really great job, using original IBM documentation for it. So that got me thinking - how hard could it be to recreate the whole motherboard for XT? I mean IBM did put the complete schematics in its Technical reference, all 10 pages of it. So I decided to do it, and it took me about two weeks to transfer schematics to KiCAD, while creating symbols and footprints, studying datasheets and now it's sort of ready for tracing. And here is where I have a problem. I have some experience with reverse-engineering old boards, with two finished projects (one is a Soviet ZX Spectrum clone, the other is a rather interesting 16-bit ISA controller for archiving data to VHS tapes called "Arvid-1020"), but I had original boards in my possession, so I could test the board for connections and continuity with a multimeter if I wasn't sure if my schematics are correct. But all I have for 5160 are several photos of varying quality, and a recently repaired XT clone that I use for a sanity check of my design. It's hard, but could be done. The second problem is much bigger. I usually place a scanned image of the board on a user layer in KiCAD, so I can use it as a reference of where to place the components. The image must be from a scanner so there are no distortions of perspective and the dimensions are correct and to scale of the whole board. But common photos are bad for it, dimensions are distorted, and I want the board to be as close to the original as possible.

So, this is my cry for help - can anyone who has the original IBM 5160 64-256kb motherboard in their possession scan it's backside with maximum quality and share the scan of it? The project will be available for everyone after testing, and I promise a huge Thanks printed on the backside of the board to all people who will help with it. Contact me on PM if you are interested in helping

So, this is my cry for help - can anyone who has the original IBM 5160 64-256kb motherboard in their possession scan it's backside with maximum quality and share the scan of it? The project will be available for everyone after testing, and I promise a huge Thanks printed on the backside of the board to all people who will help with it. Contact me on PM if you are interested in helping