iainmaoileoin

Experienced Member

I have just obtained a decwriter II (LA36) 1977 is what the label on it says. After a bit of clean and tidy, check PSUs etc, in local mode the unit (almost works). I have a pin that does not fire when the carriage is towards the left. I think the ribbon cable is frayed/faulty - - anyway I can live/fix/work with that issue.

The unit has a datasouth board upgrade. (Yes it is a decwriter II not one of the OEM versions). The fitting of the datasouth board left a few of the cables with nowhere to tie down - I think the connectors moved position from the original dec board. I can find manuals for the decwriter, but not for the datasouth board.

I have a few questions if anyone can point me in the right direction:

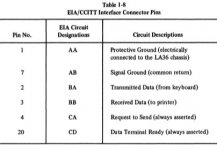

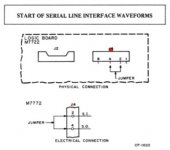

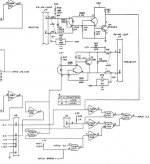

ONE I cant find any info about the RS232 (EIA) interface on the datasouth board - pin out etc. Can anyone help - what were/are the standard? (On the datasouth board I have an 20ma interface - documented, the rs232 not documented and a 25 pin "rs232" type connector).

TWO Some manuals seem to indicate the board can do 9600 baud. (The keyboard has buttons for 110/300 and press both for 1200). Am I reading newer manuals than the board version I have when it says 9600 is possible? Sure I can get the scope/data-analyser out and watch for signals.... that is a slow job for me. All clues/pointers welcome.

The unit has a datasouth board upgrade. (Yes it is a decwriter II not one of the OEM versions). The fitting of the datasouth board left a few of the cables with nowhere to tie down - I think the connectors moved position from the original dec board. I can find manuals for the decwriter, but not for the datasouth board.

I have a few questions if anyone can point me in the right direction:

ONE I cant find any info about the RS232 (EIA) interface on the datasouth board - pin out etc. Can anyone help - what were/are the standard? (On the datasouth board I have an 20ma interface - documented, the rs232 not documented and a 25 pin "rs232" type connector).

TWO Some manuals seem to indicate the board can do 9600 baud. (The keyboard has buttons for 110/300 and press both for 1200). Am I reading newer manuals than the board version I have when it says 9600 is possible? Sure I can get the scope/data-analyser out and watch for signals.... that is a slow job for me. All clues/pointers welcome.