NeXT

Veteran Member

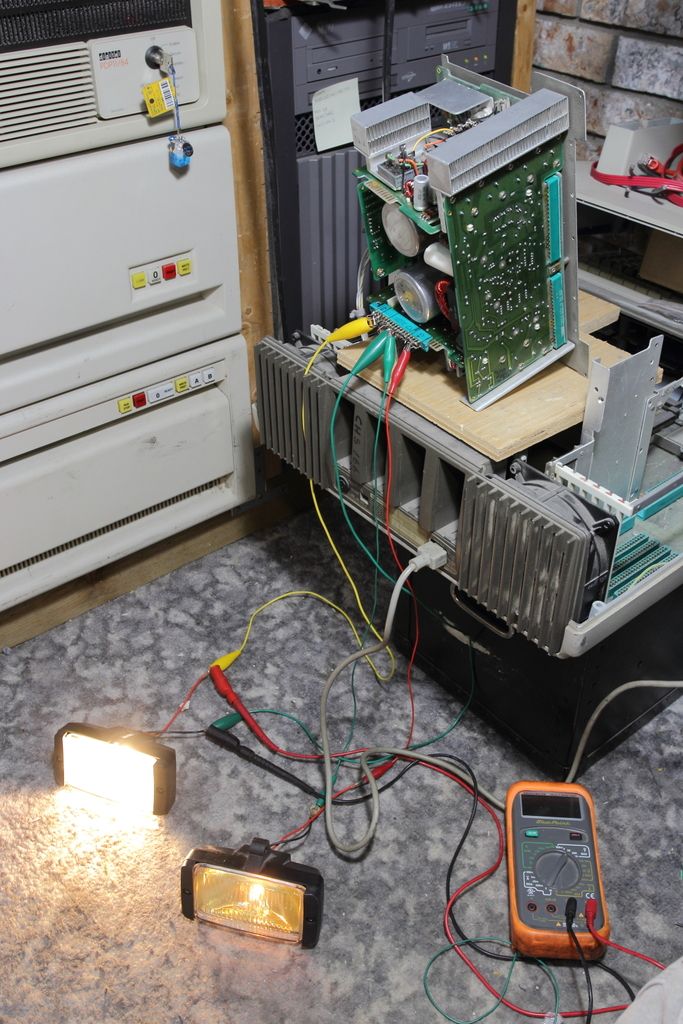

That took for goddamn ever!

...and they didn't work.

So plan B was that because the good board and my bad board were electrically he same but different revisions I stripped out the two IC's, four resistors, one filter cap and a jumper that made mine different form the other. The result is all the previously suspicious signals cleaned up immediately. Unfortunately that didn't fix it either! >:/

Another thing I noticed is I oopsed when previously testing the optocoupler and installed it backwards. I swapped them between boards so my board had a known good one and the other had the questionable one which upon testing worked so no, I didn't blow the optocoupler. The 555 was also replaced for sanity sake.

Due to the fact there's so few IC's I'll proceed with swapping chips between boards to see what happens.

Edited: Every IC and transistor on that side of the board has now been swapped between eachother and the problem did not move. Dammit.

...and they didn't work.

So plan B was that because the good board and my bad board were electrically he same but different revisions I stripped out the two IC's, four resistors, one filter cap and a jumper that made mine different form the other. The result is all the previously suspicious signals cleaned up immediately. Unfortunately that didn't fix it either! >:/

Another thing I noticed is I oopsed when previously testing the optocoupler and installed it backwards. I swapped them between boards so my board had a known good one and the other had the questionable one which upon testing worked so no, I didn't blow the optocoupler. The 555 was also replaced for sanity sake.

Due to the fact there's so few IC's I'll proceed with swapping chips between boards to see what happens.

Edited: Every IC and transistor on that side of the board has now been swapped between eachother and the problem did not move. Dammit.

Last edited: