tom.storey

Experienced Member

Hi all,

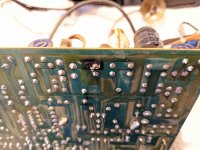

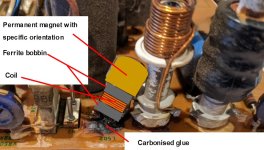

While dismantling my 5151 for cleaning today I noticed that there is an inductor which looks like it has been quite toasty at some stage. Maybe its still working(ish) because the monitor itself does work and displays an image (although there is an ever so slight "wobble" from time to time), but it looks like a bit unhappy and it could probably do with replacing.

Does anyone know what kind of part I should look at replacing it with (value, etc)? The component designator is L502, and its along the top side of the board with all of the adjustment pots.

Everything else is looking fine so far (visually), but if there are any other things I should look at doing I'd appreciate some pointers.

Thanks!

While dismantling my 5151 for cleaning today I noticed that there is an inductor which looks like it has been quite toasty at some stage. Maybe its still working(ish) because the monitor itself does work and displays an image (although there is an ever so slight "wobble" from time to time), but it looks like a bit unhappy and it could probably do with replacing.

Does anyone know what kind of part I should look at replacing it with (value, etc)? The component designator is L502, and its along the top side of the board with all of the adjustment pots.

Everything else is looking fine so far (visually), but if there are any other things I should look at doing I'd appreciate some pointers.

Thanks!