modernclassic

Member

- Joined

- May 31, 2018

- Messages

- 14

Hey all,

Longtime lurker, first time poster. I just got what I hoped was a decent deal on a PS/2 P70 that looked to be in really good shape but had a startup error that I thought might just be a dead CMOS battery. Turns out that was right and I was able to bypass the error by hitting F1 and everything else seems to work (haven't fully tested the floppy drive yet, but it's detected and spins, at least).

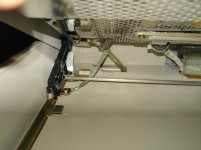

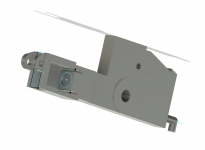

But what I discovered in testing, and I don't blame the seller for this if they didn't notice it, is that the left side hinge seems to be broken at the top. It's hard to take pics of but in the one pic under the screen below, it would be the very top of the hinge, where the pin runs through the plastic. I think the top part of that just broke off, so now that hinge isn't really holding the screen on at all - if the same thing happened on the right, I could just lift the screen off. The screen tilt mostly still works, but it's loose, and it doesn't go back in properly - it's a bit crooked, which now I can see in the original photos the seller took too. (I didn't notice at the time.) I found the piece that broke at the bottom of the screen indentation.

Is there anything I can do about this short of buying a donor system and replacing the whole assembly? How hard is it to actually remove the screen anyway? I suppose I could try to glue it back together if I could just get the screen off.

Second (and unrelated), is there any way to remove the fan to clean it? I can't even figure out how it's secured in there. Mine is crazy dirty but I have no idea how I'd clean it or the area on the motherboard behind it.

And third, now that I've replaced the CMOS battery, it does the memory test and just stops; no errors or anything. I'm assuming I need to boot from the reference disk (which I don't yet have; need to make one) but I just want to make sure what to expect so I don't accidentally select to format the hard drive or anything. What do I need to do to just get the computer to boot from the hard drive as it is?

Thanks for any help...

Longtime lurker, first time poster. I just got what I hoped was a decent deal on a PS/2 P70 that looked to be in really good shape but had a startup error that I thought might just be a dead CMOS battery. Turns out that was right and I was able to bypass the error by hitting F1 and everything else seems to work (haven't fully tested the floppy drive yet, but it's detected and spins, at least).

But what I discovered in testing, and I don't blame the seller for this if they didn't notice it, is that the left side hinge seems to be broken at the top. It's hard to take pics of but in the one pic under the screen below, it would be the very top of the hinge, where the pin runs through the plastic. I think the top part of that just broke off, so now that hinge isn't really holding the screen on at all - if the same thing happened on the right, I could just lift the screen off. The screen tilt mostly still works, but it's loose, and it doesn't go back in properly - it's a bit crooked, which now I can see in the original photos the seller took too. (I didn't notice at the time.) I found the piece that broke at the bottom of the screen indentation.

Is there anything I can do about this short of buying a donor system and replacing the whole assembly? How hard is it to actually remove the screen anyway? I suppose I could try to glue it back together if I could just get the screen off.

Second (and unrelated), is there any way to remove the fan to clean it? I can't even figure out how it's secured in there. Mine is crazy dirty but I have no idea how I'd clean it or the area on the motherboard behind it.

And third, now that I've replaced the CMOS battery, it does the memory test and just stops; no errors or anything. I'm assuming I need to boot from the reference disk (which I don't yet have; need to make one) but I just want to make sure what to expect so I don't accidentally select to format the hard drive or anything. What do I need to do to just get the computer to boot from the hard drive as it is?

Thanks for any help...