famicomaster2

Experienced Member

The 8450F will be designated with an "F" at the end of the model number sticker. These drives get a low impedance stepper which improves access times somewhat. I believe the PCB is identical between the two.I have a MiniScribe 8450. There is no letter designation after the number.

It is the 3.5" 1/2 height drive. I am assuming it is an 8 bit drive.

Is that the same as 8450F and <or> 8450A? You guys seem to know what this really is.

A YouTube video said certain drives can be RLL or MFM. Maybe this can be if the letter

at the end is the same thing for A , F and nothing?

Seems the 8450XT = 771 cyl. and 8450AT = 805 cyl. Is there a chart of all 8450's somewhere with all specs?

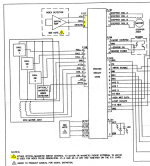

I have a 8bit DTC-5150CR control card that can do MFM only but standard BIOs doesn't show the HD 8450 size.

I would have to get the DTC-5160CR card to do DLL. I suppose that is where the 16kbit BIOS can be found, maybe?

It has only an 8 Kbit BIOS and the specs claim it needs a 16 Kbit BIOS to set the parameters manually with "special parameters".

Below Wayback specs right from Maxor/MiniScribe say it is 8450A that can be DLL or MFM but it is a 16 bit IDE interface.

I believe IDE means it is a newer drive than what I have with the single IDE cable rather than the two separate control ribbon and data ribbon.

The "A" and "X" designations are used for the IDE version - X being 8-bit and A being the more common 16-bit. There is also an "S" version which uses SCSI-SE.

With no letters at all, your drive is a bog standard 8450, which uses the ST-412 interface. This appears to the user as two edge connectors, one larger than the other. They are 34 and 20 pins, respectively. In essence, this drive is "dumb," in that is has no influence over the system whatsoever. Your controller could be writing one bit per track or be addressing only 615 of those cylinders and 2 of those heads and the drive would never know or care.

The 8450 is "RLL certified" which implies that it's media is capable of reliably storing data at 7.5 megabits, or as it will appear to your operating system, 26 different 512 byte sectors per track. Your controller is a more common unit which is only capable of 5 megabit, or 17 sectors per track, which was the standard at the time. The drive does not know or care about this - You can still use the drive, but you will lose around 33% of it's capacity due to this mismatch.

The 8450A and X are always RLL internally - As in, their onboard logic always operates at 7.5 megabits, but many PC compatible computers were still built with the expectation that every drive had 17 sectors. Thus, a drive which presents itself to the machine as having "26 sectors" might cause issues. As a result, many IDE drives implement sector translation which allows them to appear as if they had different physical geometry and report only 17 sectors for compatibility. Because your drive is not an A or X variant, you do not need to worry about this.

The BIOS will not make much of a difference to sector count - That is hard limited by the speed of the rest of the hardware onboard the controller. Because these drives are dumb, you can simply pick a different geometry which is "close enough" but less than the actual geometry of your unit. Because you have 771 addressable cylinders, the closest standards are probably the typical 615/4/17 used by many 20MB disk drives of the era (which may be represented as the Miniscribe 3425 or 8425, Seagate ST-225, NEC D5126, etc) or something close with 733 cylinders, which was a common number for many voice coil drives. I don't think many had 4 heads, though, so you would be losing an entire surface, which is undesirable. Typically they had odd numbers of heads.

tl;dr You probably have the standard 8450. Don't worry about your controller, you will miss out on some storage due to the mismatch, which will be amplified if you are limited to "standard" geometries. If you want to fully utilize this drive, it would be in your interest to put it in an AT with a "real" RLL controller like the DTC 7287 instead.