Hi community

I couldn't say to no to a NeXT computer (the slab, not the cube) complete with accessories, "working the last time it was used". While the computer's only problem seems to be a seized fan, the monitor turns out to be more problematic than I initially thought.

The monitor in question is a rebranded Sony GDM-1632, at least it matches all the parts descriptions and only lacks the weird video connector board:

When I first powered it up, the green LED turned on, but there was no high voltage and the distinct smell of capacitor juice started to emanate from the monitor. After examining the PSU and posting a picture of it on the TRW discord, it was pointed out to me that the ELNA capacitors like to be leaky and indeed they were.

I swapped all the ELNA branded capacitors except one that I didn't have stocked and was not (yet) leaking, cleaned up the PSU ("G-board") and attempted to power it on again. This time the monitor powered up including high voltage, and displayed a dim, purple picture with horizontal smears.

After a about half a minute of being on, it started to sputter and the cap juice smell came back. I further took the monitor apart and saw that the "A-board" (the color board that drives the guns I believe) has more of those ELNAs and they leaked all over the place.

I cleaned it up, replaced the ELNA capacitors on the "A-board", the neck board and one of the bigger 1000uf ELNA capacitors on the large main board ("D-board"), though that one measured still good and I was just paranoid of having to clean more of that juice. In the mean time I also replaced the last ELNA on the PSU.

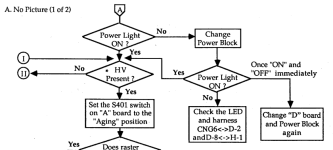

Now, after putting everything back together, whenever I switch it on the green LED turns on briefly and shuts down immediatly. I can hear a bit of degauss coil noise as well.

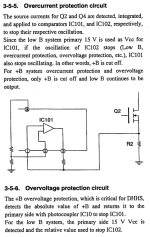

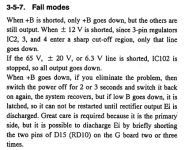

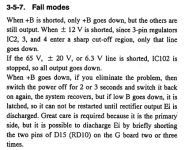

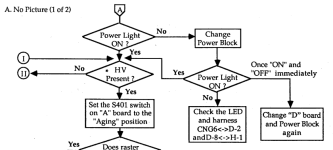

From the above linked service manual (which unfortunately doesn't have schematics):

Also:

Change "D-board" and PSU.. would be easy if I had a warehouse of those. I have disconnected all boards except the neck board and "D-board" and problem persists. Therefore my assumption is that something is wrong on the PSU or logic board.

I'm putting this out here as most threads in the internet look like people gave up on it. At the same time I'm also having a look at one of the pages (https://web.archive.org/web/20070302074640/http://repairfaq.ece.drexel.edu:80/sam/monfaq.htm) about troubleshooting monitors, but it's still a bit difficult as someone who doesn't have that much experience in SMPS / monitor repair.

Would anyone have experience in troubleshooting these monitors? It's a bit more complicated than the Commodore monitors I have encountered until now :/

I must have either introduced a fault somewhere, some component doesn't play nice with the replacement caps or something broke down randomly.

Thanks for any hints on how to try to get it back to life again! It would be nice to have a complete working setup...

I couldn't say to no to a NeXT computer (the slab, not the cube) complete with accessories, "working the last time it was used". While the computer's only problem seems to be a seized fan, the monitor turns out to be more problematic than I initially thought.

The monitor in question is a rebranded Sony GDM-1632, at least it matches all the parts descriptions and only lacks the weird video connector board:

When I first powered it up, the green LED turned on, but there was no high voltage and the distinct smell of capacitor juice started to emanate from the monitor. After examining the PSU and posting a picture of it on the TRW discord, it was pointed out to me that the ELNA capacitors like to be leaky and indeed they were.

I swapped all the ELNA branded capacitors except one that I didn't have stocked and was not (yet) leaking, cleaned up the PSU ("G-board") and attempted to power it on again. This time the monitor powered up including high voltage, and displayed a dim, purple picture with horizontal smears.

After a about half a minute of being on, it started to sputter and the cap juice smell came back. I further took the monitor apart and saw that the "A-board" (the color board that drives the guns I believe) has more of those ELNAs and they leaked all over the place.

I cleaned it up, replaced the ELNA capacitors on the "A-board", the neck board and one of the bigger 1000uf ELNA capacitors on the large main board ("D-board"), though that one measured still good and I was just paranoid of having to clean more of that juice. In the mean time I also replaced the last ELNA on the PSU.

Now, after putting everything back together, whenever I switch it on the green LED turns on briefly and shuts down immediatly. I can hear a bit of degauss coil noise as well.

From the above linked service manual (which unfortunately doesn't have schematics):

Also:

Change "D-board" and PSU.. would be easy if I had a warehouse of those. I have disconnected all boards except the neck board and "D-board" and problem persists. Therefore my assumption is that something is wrong on the PSU or logic board.

I'm putting this out here as most threads in the internet look like people gave up on it. At the same time I'm also having a look at one of the pages (https://web.archive.org/web/20070302074640/http://repairfaq.ece.drexel.edu:80/sam/monfaq.htm) about troubleshooting monitors, but it's still a bit difficult as someone who doesn't have that much experience in SMPS / monitor repair.

Would anyone have experience in troubleshooting these monitors? It's a bit more complicated than the Commodore monitors I have encountered until now :/

I must have either introduced a fault somewhere, some component doesn't play nice with the replacement caps or something broke down randomly.

Thanks for any hints on how to try to get it back to life again! It would be nice to have a complete working setup...