pinkdonut666

Experienced Member

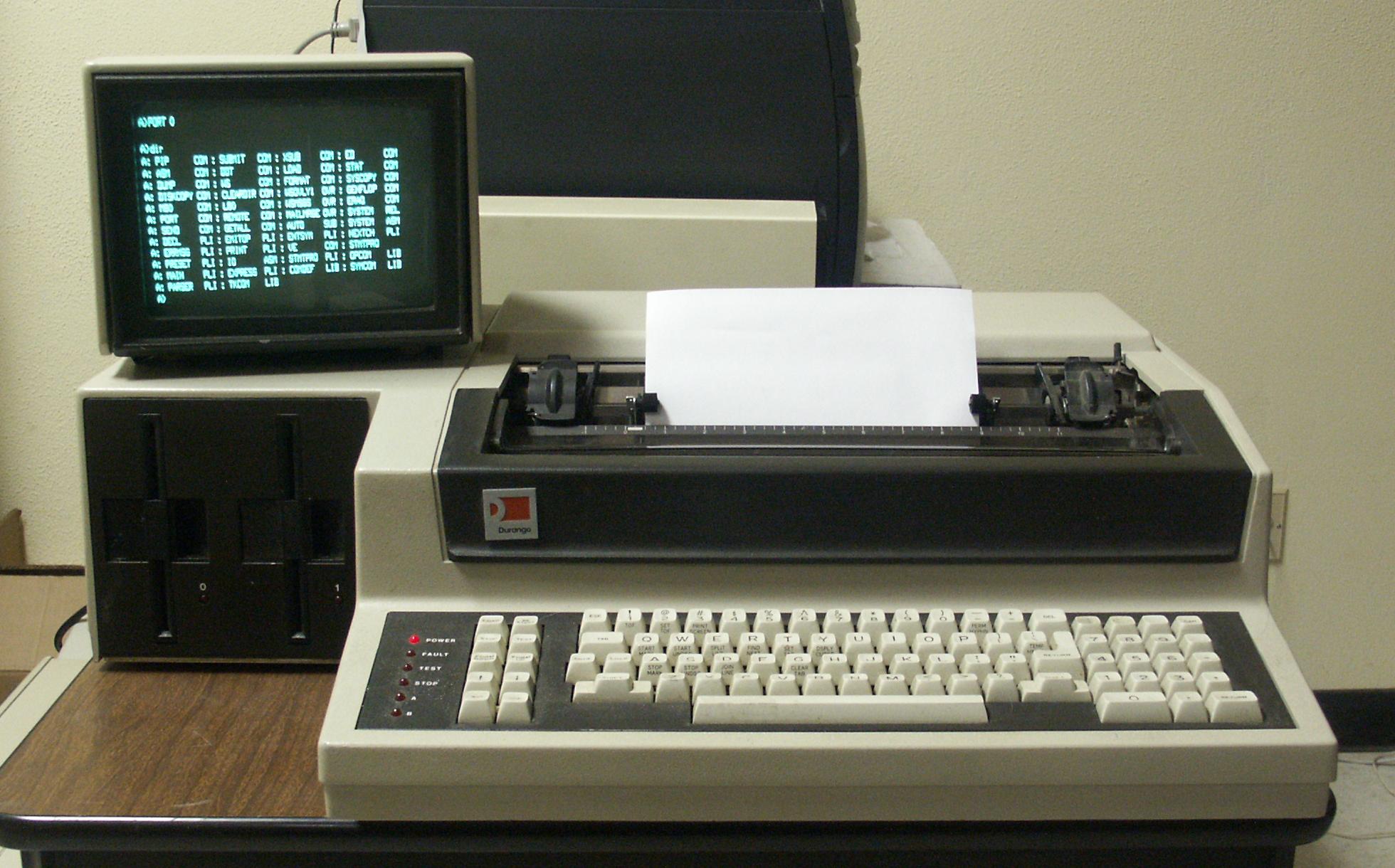

So recently I picked up a leading edge Model D that had been dumped off at a recycling center.

As you can see the machine was in very sorry shape. I was able to get it completely functional hardware wise, but I really wanted to do something about the case.

So I ground down the rusted areas with a 3M roloc disc on an air die grinder, there was actually alot of small bubbles that hid large rust patches underneath the paint.

I used this Product to neutralize any of the rust that remained. It's basically just phosphoric acid & isopropyl alcohol. The phosphoric acid turns the Iron oxide to iron phosphate (black shale like) and stops it from spreading. I didn't wanna have it bubbling up again.

and this is the somewhat finished product after a few coats of Rustolium 2X ivory Bisque spray paint. looks pretty good IMO.

now the question is whether or not I want to attempt to retr0brite the front bezel & keyboard. I'm going to leave it until the weather warms up at the very least (-20c here with 2feet of snow) so not ideal weather for retr0briting outside. But even then , not sure if i'm going to bother. The yellowing sorta gives this machine an aged charm. so I'm on the fence.

(I didn't paint the black bezel in this photo i actually found a beige bezel that matched the floppy drive better.

As you can see the machine was in very sorry shape. I was able to get it completely functional hardware wise, but I really wanted to do something about the case.

So I ground down the rusted areas with a 3M roloc disc on an air die grinder, there was actually alot of small bubbles that hid large rust patches underneath the paint.

I used this Product to neutralize any of the rust that remained. It's basically just phosphoric acid & isopropyl alcohol. The phosphoric acid turns the Iron oxide to iron phosphate (black shale like) and stops it from spreading. I didn't wanna have it bubbling up again.

and this is the somewhat finished product after a few coats of Rustolium 2X ivory Bisque spray paint. looks pretty good IMO.

now the question is whether or not I want to attempt to retr0brite the front bezel & keyboard. I'm going to leave it until the weather warms up at the very least (-20c here with 2feet of snow) so not ideal weather for retr0briting outside. But even then , not sure if i'm going to bother. The yellowing sorta gives this machine an aged charm. so I'm on the fence.

(I didn't paint the black bezel in this photo i actually found a beige bezel that matched the floppy drive better.