vrs42

Veteran Member

I'd probably have used d0cc, as it's a little newer. Don't think that's your problem, though.More interestingly the "Adder Test" maindec-8e-d0ca-pb also outputs readable text:

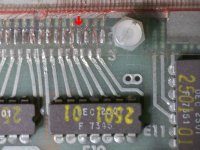

A quick check of the memory map on page 61/66 confirms that the diagnostic does not load into location 3306. Running the 'mmap' tool on the actual binary file agrees with the PDF.Unfortunately after about 30 minutes it then halts in what I think is (or should be) the "False Carry Test" (FCT).

Strangely the halting address 3306 is not shown in the listing in maindec-8e-d0ca-d.pdf which has a gap between 3270 - 3400.

It is halting right in that gap in the listing.

It looks to me like the latter, less desirable situation.This means that the document and the BIN file don't match up or that the Lab-8/E has a very weird fault. Note that it passes the first two tests.

Vince