tezza

Veteran Member

If you don't want to wade through the threads, the URL http://www.retr0bright.wikispaces.com summarises a lot of knowledge on this process to date.

Tez

Tez

| VCF West | Aug 01 - 02 2025, | CHM, Mountain View, CA |

| VCF Midwest | Sep 13 - 14 2025, | Schaumburg, IL |

| VCF Montreal | Jan 24 - 25, 2026, | RMC Saint Jean, Montreal, Canada |

| VCF SoCal | Feb 14 - 15, 2026, | Hotel Fera, Orange CA |

| VCF Southwest | May 29 - 31, 2026, | Westin Dallas Fort Worth Airport |

| VCF Southeast | June, 2026 | Atlanta, GA |

Wow, I must have not been thinking, I just got a UV lightbulb from Home Depot for $5.

Wow, I must have not been thinking, I just got a UV lightbulb from Home Depot for $5.

This was my best result to date.

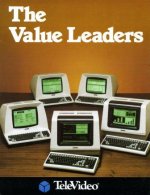

A Televideo 910, that was supposed to look like this, but didn't:

View attachment 2164

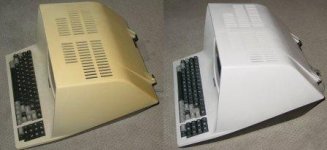

The label removed from the back side of the terminal shows what I had to deal with. This amount of yellowing on the backside and top, indicates that this Telvideo probably spent it's life backed up to a window.

View attachment 2165

This one took 5 batches of the paste/gel solution = 10 applications (washed off between every two applications). The solution was on the parts for about 2 1/2 hours at a time, after which I either reapplied it, or washed it off, and started again with another application. Total time of processing under UV light was approximately a day.

Here's the result:

View attachment 2166

View attachment 2167

This one was processed using, and needing patience (in short supply here - but apparently that's what works). I also used the Kelzan Xanthan Gum this time, and it was the first time I'd had the opportunity to use it. It makes a very nice paste/gel, easy to work with (spread around and still sticks to verticals), and I suspect it had something to do with the results.

I am really chuffed with the results on this one.

Finally, results!

Kinda splotchy, but I'm impressed with the results. Thanks, Retr0bright!

...It's a little dark and out of focus

If you notice, there was slight fading on the keys, but I'll take that to get the keys this deyellowed.