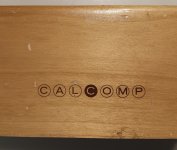

I've made a reproduction of Calcomp plotter accessory box and was wanting to know if anybody has experience with reproducing a logo like this and could recommend a method.

Suspect it was screen printed originally. Might be able to do that but seems somewhat involved. I've done toner transfer for PCB which might work. Solid areas like the middle C tended to be somewhat uneven and don't think it came out that nice looking. Thoughts? Logo is 3 inches long.

Suspect it was screen printed originally. Might be able to do that but seems somewhat involved. I've done toner transfer for PCB which might work. Solid areas like the middle C tended to be somewhat uneven and don't think it came out that nice looking. Thoughts? Logo is 3 inches long.