Thanks for your hard work Vince.

A difficulty of colours!

I thought I would return to this subject and report what I have noted.

Here are two useful resources on the subject of how humans perceive colour… it is worth watching the YouTube video to understand what is going on.

These are some of the reasons why "on screen matching" against real-world objects tends to be hard and problematic, even if the screen and graphics card are properly "calibrated".

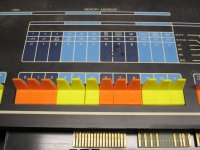

Another way to perform colour matching of real-world objects is to use "official" colour swatches (my work briefly intersected with this sort of activity many years ago). However, this is also subject to problems related to how the human eye-brain combo perceives colour. Below are two images of an "amber" handle against some "official" RAL colour swatches. The "daylight" image was taken outside in natural daylight, but on an overcast day (that’s what we have at here the moment). The other was taken inside under LED lighting. Spot the difference! It is even more obvious in person (probably because of the phone camera’s limited gamut and that it’s all RGB only).

I believe the differences here are because of the variances in the wavelength coverage and intensity of light from the two sources and how much of these are reflected and absorbed by the different pigments in the two items (the swatches and the plastic of the handle)… Under florescent lighting it was different again; using the flash also makes it different again. In slightly brighter daylight the handle matched more closely with one of the other RAL swatches. I have been waiting for direct sunlight – but it is winter time here so that hasn't happened…!

The terra cotta handle in the images is a red herring as it does not appear to match well with any of the available swatches in the lighting conditions tested so far. Note that I also only have a small set of swatches.

I expect all this makes it hard to get a paint/paint-mix that can be used to paint a green/wrong colour switch so that it matches an original amber or terra cotta plastic handle under different lighting conditions. So it is probably a case of getting a "close" matching paint and then painting all the handles (for replacement purposes). Or, maybe, an "indistinguishable" amber/terra cotta paint for the wrong coloured switch under the lighting conditions the system will usually be seen under. One potential issue with painting the switches is choosing a paint that won't affect the plastic in a bad way, or chip/rub off too easily.

I will attempt a low-cost RAL paint mix at some point.

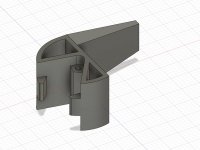

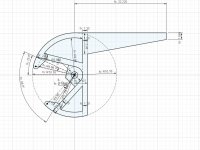

It is likely no easier to 3D print a handle using "colour mix-matched resin" (even if that is practical to do: WIP) that matches perfectly (so a complete set would have to be produced).

I have noticed in various photos that the colour of the handles is not an exact match for the legend colours on the panels… so, as long as all the handles are perceived as being the same colour as a set, a "satisfactory" colour choice is probably okay.

Note, also, that the current 3D model is not a precise match for the actual handles. I will look into trying to produce something with "OpenSCAD" at some point.