On the colors you have come up with, Do you have the RAL code that most closely matches? I look forward to your update.

An update. The second half of the following is mostly about "RAL Design" colours and the use of paint. See also: "freebies".

RAL Classic: there aren't sufficiently good (in my opinion) matches; there aren't that many RAL Classic colours. I will retest RAL Classic again and tabulate the "best" of the RAL Classic matches under different lighting conditions (the worse the match is, the greater the variation in the visual separation in different lighting conditions) later (in a day or two; in another post). See also: "Which colours?".

RAL Effect: the matches with RAL Design are probably better (the Terra Cotta definitely needs to be retested with RAL Effect now that we have something better to measure it against).

Other "colour charts": possibly there are better matches available; but fewer choices of supplier. Now that I have another verifiable "datum" (as below) I will scan through some of the other available colour charts in paint (including RAL Effect) to see if I can identify potentially better matches.

Bespoke paints: expensive looking (but could be investigated).

Or: Paint mixing, by spraying two at a time, is a possibility for a better result (needs practice and the right choice of colours)? See experimental results described below.

Coloured 3D printed resin: I didn't find any purchase options for "parametrically specified colours". So, as far as I know, this will still require to be mixed by hand to learn the mix recipe; which is likely dependent on what resin is used.

Coloured 3D printed filament: I haven't seen any practical mixing/colourization options, nor RAL Design options; the RAL Classic colours are available.

Finding definitive colours

A lot of time spent with maths and the web, and various other things trying to narrow things down! Result: too many possibilities with variations, depending on which resource one looks at, that are not really verifiable without spending money to test each one.

Many of my investigations started with searching for colour chart matches with sRGB values from the table Vince has prepared:

http://svn.so-much-stuff.com/svn/trunk/so-much-stuff.com/pdp8/repair/dec-std.html

But different resources match (near matches), for example, different sets of RAL colours for the given sRGB values. Different resources even quote different sRGB values for a given RAL colour. Even coding up searches myself results in too many [electronically] unverifiable choices. And so on.

Which colours?: this whole search has raised a couple of additional "questions"...

The first being that the switches I have have been obtained "loose" (i.e. they were removed from a machine(s) at some point in the past and later acquired by me; so have no provenance). I have started to wonder if they are from an /F, /M or even /L (even if there seems to be some evidence these machines might have all used the same

sets of colours). The switches I have have the right part numbers for an /E, and I think they look "okay" colour wise.

Secondly, I am also starting to suspect, maybe, that there may have been at least two versions of "Amber", even for the /E. For example:

Code:

Relevant colours from EL-00092-00-0_F_Finish_and_Color_Standard_Dec82.pdf

141 PDP8/E Amber MUN (10YR6/12), CHM 3

142 PDP8/E Terra Cotta CHM 5 PE

Also note it gives:

136 PDP14 Amber MUN (10YR6/10), CHM 3

That's at least two different colours mentioned for either the PDP-8/E or the PDP-14; and I believe/suspect it is three because I haven't been able to discover or prove that either of those Munsell codes are the same colour as CHM 3!

So, rather than waste money on a wide range of different coloured paint to test with, a different course...

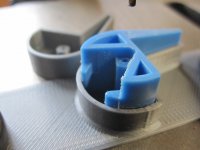

I have recently obtained official RAL Design plus (D2) swatches and used them to identify the two

visually closest RAL Design codes for "Amber", and the two closest for "Terra Cotta", when compared to the the switches I have in my possession.

I have then purchased acrylic paint of these four RAL Design colours and painted the resin prints from thingiverse.

Observations include:

- The paint might not 100% match the RAL swatches (but is very close; it could be a texture and/or glossiness thing).

- Likely to be true: the closer the match in the colours of the genuine handle and the replica, the better the match in all lighting conditions.

- I think that, potentially, the images below (from my phone's camera) sort of accentuate the differences more than they appears in real-life (tested under artificial light).

- Texture and gloss can have an effect on colour perception.

- Lighting can have an effect on colour perception (normally your brain "auto-corrects"; until you compare things side by side).

- There are other paint systems that might have a better match.

Freebies (for a limited time at least): I have painted some card stock with the paints described below and could send them out in "late" Christmas/New Year cards to interested parties to compare with their machines. And maybe also send some colour patches for reference photos (colour patches might/might not be a useful idea - I only thought of it a few hours ago and have not tested the idea).

The paints used are acrylic enamel spray paints with UV protection and 60% gloss. No hardener (so that it is not single use can of paint) - still it actually seems quite tough; I will do a "wear test" on it soon. There were two layers of primer and about eight thin layers of paint.

In the picture above (all images taken under bright fluorescent light):

Amber:

The switches/handles are sat on card stock painted with "

RAL 070 60 75"; visually I think this is a better match to the amber switch handle than the "

RAL 070 60 70" that has been used to paint the thingverse handle to the right.

Terra Cotta:

The thingiverse handle in the middle has been painted with "

RAL 050 40 50"; this is definitely too dark; but is not unpleasant, and possibly the best of the two for the Terra Cotta handles if one was to stop searching at this point.

The leftmost thingiverse handle was painted with both "

RAL 050 40 50"

and "

RAL 050 50 60" by spraying it with both paints at the same time. This was an experiment: because those two colours are the best visual matches with the swatch, but neither seemed as good as the amber matches are with the amber handle, and one looks lighter, the other darker. I think the result is a better visual match than either of the colours on their own.

In isolation (and trying to forget there is a mismatch) "

RAL 070 60 75" and "

RAL 050 40 50" might be the best choice.

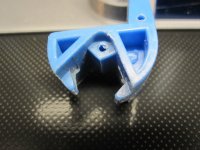

The image below shows the switches sat on card stock painted with "

RAL 050 50 60" - however the photo makes it look more orange than it actually is.

Note: colours seen in the images will vary depending on display device.