Hello Rich, yes I have a print for the open frame S-100 project (enclosed). It is based on the

older version of the S-100.com 8-slot motherboard. It should work for the 9-slot one with

adjustments. The card guides were purchased from Mouser (Bivar VG2-5). You don't need the

power-on delay relay setup but I like it as it prevents me from removing cards with power on and

it allows the supply to stabalize during turn-on (mainly for linear supplies-not so much for the

switchers).

>>> Charles

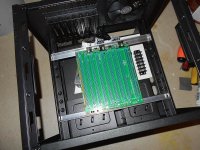

I got around to building this setup (converting from my CompuPro cage-on-plywood) and it's an excellent design that was pretty easy to build. My bottom frame was about 1/2" shorter so I had to adjust the offsets on each end to make up for it.

Overall, the diagram was very thorough and was easy to build from. Here are a few observations and suggestions:

* Multi-decimal measurements are very hard without a digital caliper since I didn't have a tenths-ruler. There was enough wiggle-room in the holes that any inaccuracy did not have much of an impact.

* Having the drill hole dimensions was helpful, but the intended screw size (4-40 or 5-M3) wasn't indicated.

* The mounting screw sizes on the bottom of the S-150 supply are 5-M3 and the sides are 3-M3. Since I didn't have metric screws, 4-40 worked, but when all you have is a hammer, everything looks like a nail as they say.

* My plastic board was shorter by about 1/2", so I mounted the power supply stack so that the sheet metal lined-up with the outside edge and I shifted the entire board stack to the left a little. I also moved the power supply stack further back to accommodate a small switch/LED panel I used on my other setup. If the plastic sheet has a paper protective layer, drawing this out is easy. Mine didn't have that (it's a satin black base). So, blue 3M painter's tape, a center punch, and a Sharpie worked well for this purpose.

* I would recommend mounting the middle power supply 1/2" forward of the current dimension so that you can wire-up the supplies when mounted to the metal (I built it as a sub-assembly). If they're mounted in-line, you can't get to the screws.

* I did not use fuses, although I drilled the holes for the holders. These supplies have short circuit protection which of course doesn't necessarily protect the traces. I've never had an issue, but I can add them later. I was looking into self-resetting fuses for it...the new revisions of the backplane have that, but the older ones have an error in which the PTCs protect the LEDs and not the slots. Those LEDs are expensive you know

* I'm a little concerned about the accumulation of static on the plastic; not sure how to deal with that, but I guess the cage of the power supply "connects" to the base through the mounting screws. I punched some card stock and put it under the backplane for good measure. I did not use copper tape or anything.

* For power input, I have an "input block" which has a switch, IEC connector, fuse and line filter in a single package. I mounted it in a piece of wood which I then mounted on the board behind and inset to the power supplies so that the 0.25" terminals clear the S-150 supply. I did not build the relay part of the setup.

All I'm waiting for at this point is a new spool of black 16AWG wire I ordered, and then I can finish wiring the supplies to the backplane.

Thanks again for a great design and sharing it with the list!

Rich