voidstar78

Veteran Member

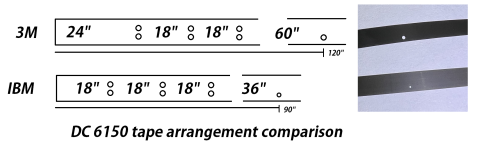

I've gotten some 3M DC 6150 tapes, to try on an IBM 5110 with internal tape deck.

Results are inconsistent, so I'm looking for anyone experienced on how the workflow is "supposed" to work.

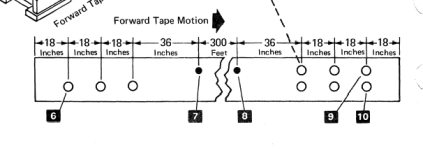

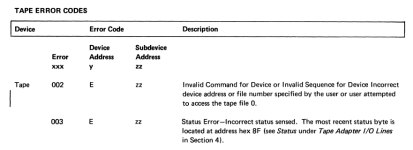

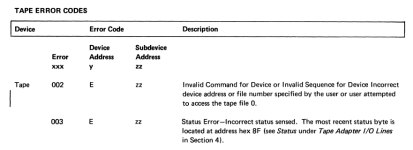

I can issue a REWIND, and it sometimes works (the tape physically spun). Other times I get ERROR 003 E80. On a "brand new" tape, is REWIND necessary? I know there are "BOT" and "EOT" markers that are supposed to be on the tape media itself.

UTIL doesn't work for me, since I assume it identifies there is no content on the tape.

If I remove the tape and try certain commands, I get ERROR 005 E80 (i.e. it is identifying the presence and non-presence of the tape)

I just insert the tape until I hear a couple light "magnetic clicks".

MARK 3,2,1 command is also giving me ERROR 003 E80.

Page 4-96 (page 218) of the MIM located here: <<http://www.bitsavers.org/pdf/ibm/51...er_Maintenance_Information_Manual_Feb1979.pdf>> states this...

Could it be the 3M DC 6150 tape is incompatible or just bad? (it's a "new stock" 150MByte 620ft version)

If the tape is all good, then should these steps work:

- insert the tape

- issue REWIND

- issue MARK 5,5,1 (5K per file, 5 files, starting with index 1) (this also format/overwrite anything that might already be there?)

- issue SAVE 4,'TEST' (probably will error if there is "0 bytes to save" - so make up some simple program first)

- issue REWIND

- issue LOAD 4

Results are inconsistent, so I'm looking for anyone experienced on how the workflow is "supposed" to work.

I can issue a REWIND, and it sometimes works (the tape physically spun). Other times I get ERROR 003 E80. On a "brand new" tape, is REWIND necessary? I know there are "BOT" and "EOT" markers that are supposed to be on the tape media itself.

UTIL doesn't work for me, since I assume it identifies there is no content on the tape.

If I remove the tape and try certain commands, I get ERROR 005 E80 (i.e. it is identifying the presence and non-presence of the tape)

I just insert the tape until I hear a couple light "magnetic clicks".

MARK 3,2,1 command is also giving me ERROR 003 E80.

Page 4-96 (page 218) of the MIM located here: <<http://www.bitsavers.org/pdf/ibm/51...er_Maintenance_Information_Manual_Feb1979.pdf>> states this...

Could it be the 3M DC 6150 tape is incompatible or just bad? (it's a "new stock" 150MByte 620ft version)

If the tape is all good, then should these steps work:

- insert the tape

- issue REWIND

- issue MARK 5,5,1 (5K per file, 5 files, starting with index 1) (this also format/overwrite anything that might already be there?)

- issue SAVE 4,'TEST' (probably will error if there is "0 bytes to save" - so make up some simple program first)

- issue REWIND

- issue LOAD 4

Last edited: