Lou - N2MIY

Veteran Member

I have started another impossible project. I got a bad RD53 (Micropolis 1325) from fellow forums fan, Marty.

I have scoured the internet for all I could learn about this most infamous of MFM hard disks. They usually have at least one of two common problems - stuck heads or spindle motor problems. The one I have has spindle motor problems.

Of course, no print set has ever turned up. However, the dec technical manual was photographed from fiche, which I have downloaded and devoured.

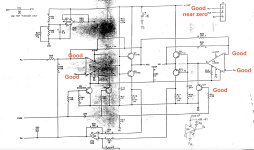

The spindle motor is a three pole brushless dc motor. Commutation synchronization is provided by three hall effect sensors. There are eight permanent magnets mounted inside a ring (the rotor) screwed to the spindle. Each pole is driven by its own TIP125 darlington pair. Power comes from the 12V supply, and all poles power goes through a low value resistor used for current sensing (and limitation circuit). The drive is unipolar and there is only one pole powered at a time (by design).

I reverse engineered most of the motor driver circuit from the board traces. I repaired one broken pole driver and another that was used for the brake solenoid. The electronics all appear to be working as they should. But, the motor will still not come up to full speed (3600 RPM)!!!

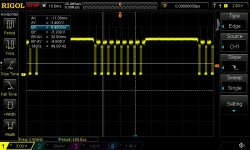

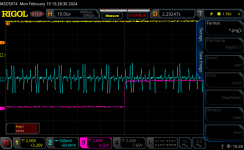

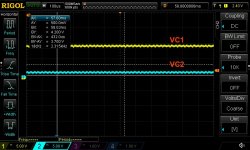

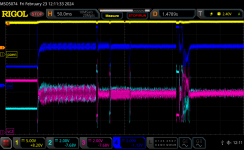

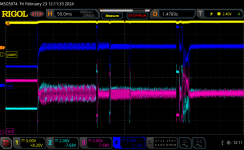

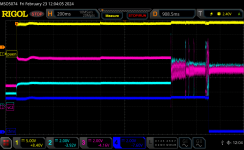

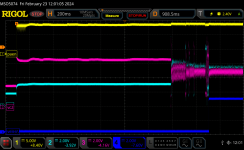

The drivers are driving hard, and the synchronization with the rotor looks pretty good on the scope. But there are two weird things.

1.) one of the sensors seems late by a small angular amount

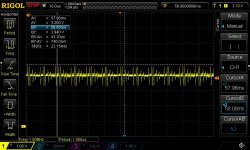

2.) the sensor duty cycle is weird. The "on" time is 2/3 of the "off" time. In the diagram in the tech manual, the duty cycle is 50/50 (as it is in all other examples of hall effect commutation on the internet). I tried removing the rotor and shimming it slightly so that it was about 0.010" farther from the sensors. No change.

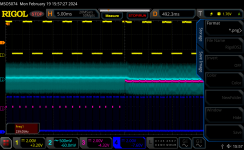

However, the actual driving of the poles looks good on the scope. The current limiting circuit only kicks in during starting. I can bypass it and spin up faster, but either way, it only goes to 3/4 speed and stays there. The rotor is very well balanced.

If I use an adjustable 12-15V supply, I can spin the motor faster. I only went to 12.6V though, because there is a 5V reference generated with a zener regulator from the 12V source and the zener was getting hot. It does regulate properly though. I think I'd need about 16V to actually get to full speed.

I've seen youtube spinups of the RD53, and they get up much faster than mine.

I think one of two things is the problem:

1.) There is more spindle bearing friction than there should be. It feels ok though and doesn't make any noise?

2.) I'm no physicist, but can the permanent magnets lose their magnetism? Googling that made me think it's possible, but why does the youtube guy's drive still work? It would explain the loss of torque and strange hall effect sensor duty cycle.....

So, if you have an RD53 doorstop that you're willing to donate to science, let me know. I want to put your magnet ring on my drive. I also want to compare how stiff your spindle bearings are.

Any comments or insights are welcome. Maybe we can make some progress toward salvaging some of these doorstops.

Lou

I have scoured the internet for all I could learn about this most infamous of MFM hard disks. They usually have at least one of two common problems - stuck heads or spindle motor problems. The one I have has spindle motor problems.

Of course, no print set has ever turned up. However, the dec technical manual was photographed from fiche, which I have downloaded and devoured.

The spindle motor is a three pole brushless dc motor. Commutation synchronization is provided by three hall effect sensors. There are eight permanent magnets mounted inside a ring (the rotor) screwed to the spindle. Each pole is driven by its own TIP125 darlington pair. Power comes from the 12V supply, and all poles power goes through a low value resistor used for current sensing (and limitation circuit). The drive is unipolar and there is only one pole powered at a time (by design).

I reverse engineered most of the motor driver circuit from the board traces. I repaired one broken pole driver and another that was used for the brake solenoid. The electronics all appear to be working as they should. But, the motor will still not come up to full speed (3600 RPM)!!!

The drivers are driving hard, and the synchronization with the rotor looks pretty good on the scope. But there are two weird things.

1.) one of the sensors seems late by a small angular amount

2.) the sensor duty cycle is weird. The "on" time is 2/3 of the "off" time. In the diagram in the tech manual, the duty cycle is 50/50 (as it is in all other examples of hall effect commutation on the internet). I tried removing the rotor and shimming it slightly so that it was about 0.010" farther from the sensors. No change.

However, the actual driving of the poles looks good on the scope. The current limiting circuit only kicks in during starting. I can bypass it and spin up faster, but either way, it only goes to 3/4 speed and stays there. The rotor is very well balanced.

If I use an adjustable 12-15V supply, I can spin the motor faster. I only went to 12.6V though, because there is a 5V reference generated with a zener regulator from the 12V source and the zener was getting hot. It does regulate properly though. I think I'd need about 16V to actually get to full speed.

I've seen youtube spinups of the RD53, and they get up much faster than mine.

I think one of two things is the problem:

1.) There is more spindle bearing friction than there should be. It feels ok though and doesn't make any noise?

2.) I'm no physicist, but can the permanent magnets lose their magnetism? Googling that made me think it's possible, but why does the youtube guy's drive still work? It would explain the loss of torque and strange hall effect sensor duty cycle.....

So, if you have an RD53 doorstop that you're willing to donate to science, let me know. I want to put your magnet ring on my drive. I also want to compare how stiff your spindle bearings are.

Any comments or insights are welcome. Maybe we can make some progress toward salvaging some of these doorstops.

Lou