eeguru

Veteran Member

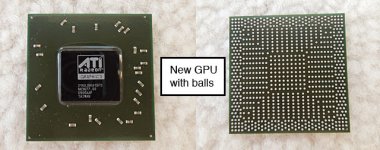

I think you need to find a ruler and measure how small a .4mm ball pitch is.

.8 and 1mm BGA can be done with a home oven. However the boards are prohibitively expensive for hobbyists to order. For 1mm pitch the dog bones require 10 mil drills and 5 mil rings. That beyond most bargain PCB's DRM rules. .4mm is solidly in HDI territory which adds up to significant dollars for small runs of boards.

.8 and 1mm BGA can be done with a home oven. However the boards are prohibitively expensive for hobbyists to order. For 1mm pitch the dog bones require 10 mil drills and 5 mil rings. That beyond most bargain PCB's DRM rules. .4mm is solidly in HDI territory which adds up to significant dollars for small runs of boards.