Chuck,

This is an EXCELLENT question...and quite frankly, before you asked, I hadn't even considered the belt removing the oxide as an option. So, I suppose I would need a really high-grade high-power stereo microscope to see whether these are raised spots or depressions, in order to really tell, but here's what I can determine with the meager tools that I do have.

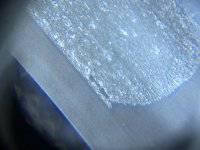

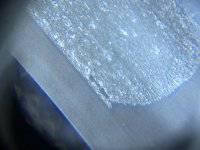

Using a 60x magnifier and light attachment to my iPhone, I see this image of beginning edge of area of the tape affected by the belt contact. We really can't tell, and a side profile of the edge of the tape is useless with this low quality magnifier, as it has no depth to see whether these are raised areas or depressed areas.

Now, thanks to you and others on a

previous thread on this forum, I got myself some

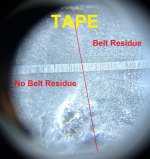

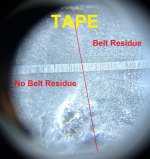

Kyread SDF-130A solution. I've applied this to the area of the tape right on the edge of the area affected by the belt.

On the magnified shot, the kyread solution obscures the mark left by the belt, but I can still just where it begins with the naked eye. I've marked the delineation here:

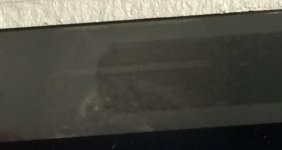

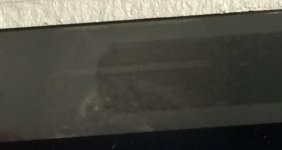

And then, this is more how it looks with the naked eye under regular lighting.

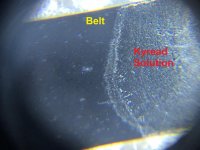

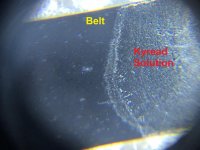

And then, I applied the Kyread to the belt itself, in the area where it was against the tape. The Kyread doesn't seem to have anything special going on in the area where I would expect that "data line" could be.

Of course, all of this doesn't mean that the pulling away of the oxide still didn't happen, and can affect it in a way that the Kyread doesn't display using this method, but it's encouraging that this stuff might just be residue on the tape itself, and the magnetic signal is still under there intact.

As always, I love the responses here. This is a great discussion for me.

Thanks again,

-AJ