Well.... I've made some progress, but it's not clear where the problem is yet. I tried to monitor the interrupts and I don't think the problem is with the interrupts. I only get an interrupt when the FDC is busy with a read or when the seek occurs. I believe the problem is with the Siemens Drive. Although the Siemens will work alone as Drive A. When it is connected to as a second drive, the system fails. By this I mean the 8080 will run, but I can not boot CPM. I've tried making each drive the first or the second, no change.

Then I tried blocking RAW DATA pin 46 on the Siemens and this allowed CPM to boot from the Shugart drive as A. The Siemens was set to be drive B. In fact I tried making the Siemens drive to be #8 on the binary select, with no results. Seems odd, the Siemens was not selected nor was the head loaded. Having a disk in or out of the drive made no difference. So, I guessed that maybe the output gate to pin 48 (7438) was bad. So instead of replacing it, I have another Siemens drive and tried exchanging the circuit board. Now with the Siemens as drive B, I can boot from the Shugart as Drive A. BUT the Siemens could not be accessed. So I tried the Siemens alone as Drive A and it didn't work here either.

So, I checked all the jumper options. There are two jumpers that are different between the two boards. Problem is Siemens doesn't use shorting bars for these options. They are soldered in place. In fact the board that works as Drive A has the factory jumpers changed and it looks like it was a difficult change, the traces are a little butchered. So I'm reluctant to make these changes without understanding what I'm doing.

The Siemens is a FDD-100-8E. Jumper C, looks like when it is closed it will supervise INDEX and SECTOR (not used in this application) with READY. The board that works has an added jumper here. The other broad has it open (factory setting). I don't think that this is the problem. READY just means the disk is up to speed, the door is closed and the voltages are good. So, this should have little to do with INDEX.

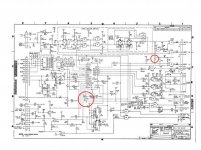

The other jumper is more mysterious, It's labeled F, G & H. There are four pads that can be connected, fashioned in a TEE. I think that the arms of the TEE are the F and H jumpers and the stem is the G jumper. This setting is a little harder to understand from the schematic. The text in the manual I have doesn't mention these jumpers. The G pad connects to an inverted Head Load line. The F pad is ground. The H pad is connected to the SELECT line. The center pad (center of the Tee) is connected to the input of an inverter which goes to a multi purpose chip input called PHASE OPT. This pad also goes to what looks like step inhibit circuitry. The manual doesn't talk about PHASE OPT (phase option?) The board that works has a jumper between the Center Pad and F the ground. So either this turns the PHASE OPT on or off directly. The board that doesn't work has the jumper between G & H. This connects the multi purpose chip output of Head Load through another inverter (G) to the center pad thru an inverter to the PHASE OPT. In other words PHASE OPT = HEAD LOAD.

I've monitored some of the inputs from my FDC. Looks like the SELECT works, the input to the head load is there, but the head never loads. The in use light on the front of the drive never lights. So, I don't know whether either board is OK. The second board may just need a jumper change. Does anyone know what this 'PHASE OPT' is? Mike