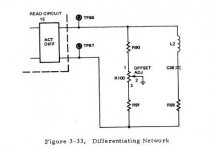

Over the past week or so, I've been having a boat load of hardware problems with my 8" drives. A couple of capacitors failed, a belt broke, two more head pad flew off, one got caught in the AC drive motor and a few other items. In the mean time I picked up another Siemens FDD-100 drive. They said it didn't work, so I got it cheap. So I connected it up to my test box. First it didn't have a head pad, image that. Next the head was not loading properly, the J5 plug was plugged into J4. After I fixed these and changed the jumpers for my purpose, I could get the drive to select, and the head to seek correctly. There were no read pulses at all. So I fiddled with R100 again. I preset it to the same resistance values as my other Siemens drive that works and all of a sudden there were read pulses, but I could not get it to function correctly. It would not work with my 8080 machine, or 22DISK or IMD. The speed test on IMD would not work, yet I have nice index pulses at the correct spacings. I saw these on my scope. So I checked the write protect, and ready lines they are working OK. I looked at the read pulses with my scope and tuned R100 for the best read pulses. I then compared read pulses of this Siemens drive with the other one that works and the Shugart. They all look similar, yet the drive that doesn't work has a little larger ringing.

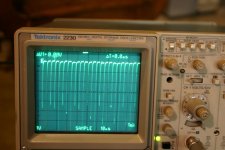

View attachment 24052

This a read pulse on the Siemens that doesn't work

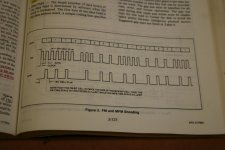

View attachment 24053

This a read pulse from the Siemens that works

View attachment 24054

This is a read pulse from the Shugart

The difference that I see is that the ringing on the bad Siemens is a little larger. Maybe one of the crests is being seen as a high? I was also concerned about the negative swing, but they all have them, so......

I can't figure why this new Siemens will not read any ideas or suggestions. Thanks Mike

![IMG_0077[1].jpg IMG_0077[1].jpg](https://forum.vcfed.org/data/attachments/18/18414-652ebbe1d71609e02fcf1a2d4c022d42.jpg?hash=ZS674dcWCe)