Merlin

Experienced Member

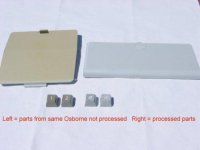

So far, we haven't found any parts that have "overcooked".

Plastic parts are pigmented and the peroxide won't bleach the pigment as it's encapsulated in the plastic.

If the part was intended to be white, it may eventually get there, however I can't guarantee that you will get to "as new". Some Amiga keys that were cleaned turned grey instead of the slightly brown shade we normally see, but I suspect that Commodore intended them to be grey originally and that they slightly discoloured during the moulding process.

Eventually, the peroxide solution will deplete, it may take a couple of days though. You should be able to treat a couple of batches of parts before it loses it's power.

I can't wait to see the pictures....

Plastic parts are pigmented and the peroxide won't bleach the pigment as it's encapsulated in the plastic.

If the part was intended to be white, it may eventually get there, however I can't guarantee that you will get to "as new". Some Amiga keys that were cleaned turned grey instead of the slightly brown shade we normally see, but I suspect that Commodore intended them to be grey originally and that they slightly discoloured during the moulding process.

Eventually, the peroxide solution will deplete, it may take a couple of days though. You should be able to treat a couple of batches of parts before it loses it's power.

I can't wait to see the pictures....