NF6X

Veteran Member

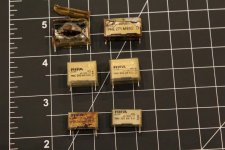

When I researched for a replacement for one of those Rifa paper dielectric caps that blew in my TRS-80 Model 12, I decided to replace all of the paper dielectric caps I encounter with polyethylene or polypropylene film safety-rated caps. I read that the paper dielectric is prone to absorbing moisture if the case is not perfectly sealed, so I hypothesize that the failure mode of these Rifa caps is for the case plastic to crack due to aging, allowing moisture to seep in, which then results in dielectric breakdown when they're energized. Followed by lots of smoke and the smell of burning aluminized paper. I haven't replaced those caps on my newly-acquired 5322 yet, but that's on my short list.

If Wikipedia can be trusted, then poly film caps are much less prone to moisture absorption, even if not hermetically sealed. Thus, I decided to search for poly film caps with similar ratings as replacements.

If I remember, I'll try later today to dig up the part numbers of the caps I chose to replace the Rifa caps that I found in my TRS-80 power supplies. Identical new (?) Rifa caps are still available, but I don't trust them. The part numbers I picked out might not be perfect matches for what you need, but they should at least help you narrow down your search through the tens of thousands of caps that Digi-Key carries!

My replacements had different lead spacings than the originals, but the Astec supplies in my TRS-80 computers had multiple holes for those caps to accept caps with different lead spacings. They apparently planned ahead to be able to source different caps in production.

BTW, I just now found this thread, and the link you posted with information about the power-on diagnostics is helpful. Thanks!

If Wikipedia can be trusted, then poly film caps are much less prone to moisture absorption, even if not hermetically sealed. Thus, I decided to search for poly film caps with similar ratings as replacements.

If I remember, I'll try later today to dig up the part numbers of the caps I chose to replace the Rifa caps that I found in my TRS-80 power supplies. Identical new (?) Rifa caps are still available, but I don't trust them. The part numbers I picked out might not be perfect matches for what you need, but they should at least help you narrow down your search through the tens of thousands of caps that Digi-Key carries!

My replacements had different lead spacings than the originals, but the Astec supplies in my TRS-80 computers had multiple holes for those caps to accept caps with different lead spacings. They apparently planned ahead to be able to source different caps in production.

BTW, I just now found this thread, and the link you posted with information about the power-on diagnostics is helpful. Thanks!